- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Why Turndown Ratio Matters in Flowmeter Selection

Flow measurement is central in many industrial systems. Choosing the right flow meter improves accuracy, reliability, and cost efficiency. One often-overlooked parameter is the turndown ratio.

This article explains what turndown ratio is, why it matters, how it affects the performance of a flowmeter, and how to select a flow meter with the right turndown ratio.

What Is the Turndown Ratio?

The turndown ratio (also known as rangeability) is the ratio of the maximum flow a meter can measure to the minimum flow it can measure while maintaining acceptable accuracy.

Mathematically:

Turndown Ratio = Q_max / Q_min

Here, Q_max is the highest flow rate for which the meter maintains its specification, and Q_min is the lowest flow rate for which it still meets that specification.

If a meter has a 20:1 turndown, it can measure down to 5 % of its full scale.

A meter rated for 100 to 1000 units of flow has a turndown = 1000 / 100 = 10:1.

Why Turndown Ratio Matters

A flow meter with the right turndown ratio does several things:

- Covers variations in flow

Many processes do not run at a fixed flow. They fluctuate depending on demand, load, or operating stage. A meter with too narrow a turndown will lose accuracy at low flow or fail to read small flows. - Avoids “lost flow” or measurement gaps

If your meter cannot measure below a certain lower limit, any flow below that limit is not recorded or is erroneous. In steam or gas systems, these losses can accumulate. For example, a flow meter for steam sized with a 4:1 turndown may “lose” a large portion of steam during low-flow periods. - Reduces the need for multiple meters or ranges

If your meter can handle a wide span, you may not need to install different meters for low flow and high flow. This saves on instrumentation, installation, and calibration costs. - Improves process control and responsiveness

A high turndown ratio gives flexibility in controlling the process across a wide range. You can adjust the flow finely, even at lower rates. - Balances cost and performance

Very high turndown designs may be costlier or more complex. You must match the turndown to what the process actually needs, not over-specify.

How Turndown Ratio Varies by Meter Type

Different flow meter technologies offer different typical turndown ranges. Below is a summary:

| Meter Type | Typical Turndown Ratio | Notes |

|---|---|---|

| Orifice (differential pressure) | 3:1 to 10:1 | Low ratio because differential pressure drops off at low flow. |

| Turbine Flowmeter | 10:1 to 20:1 | Good for clean fluids and moderate range. |

| Positive displacement (diaphragm, rotary) | 10:1 to 80:1 | Depends on design; good for low flows. |

| Ultrasonic Flow Meter (multipath) | ~50:1 | No moving parts helps maintain accuracy. |

| Thermal mass flow meter / mass flow | 100:1 or more | Very wide range, useful for gases. |

| Magnetic Flow Meter (for conductive liquids) | Up to 150:1 | Good range for water and conductive fluids. |

| Vortex Flow Meter | 10:1 to 30:1 | Moderate range, good for steam, gas. |

These are typical values; actual turndown depends on design, manufacturer, sensor quality, and installation.

Practical Steps to Use the Turndown Ratio in Selection

Below is a guide to applying turndown in your flow meter selection.

- Define your expected flow range

Identify your lowest expected flow and highest peak flow. Your meter must cover that span. - Compute the needed turndown

Divide the max flow by the min flow to get the required ratio. - Check meter specifications

Confirm that the candidate meter’s turndown ratio meets or exceeds your requirement. - Check accuracy at the low end

Make sure accuracy does not degrade excessively near the lower limit. Many meters lose accuracy near their Q_min. - Consider noise and signal issues

In low flow conditions, the signal-to-noise ratio becomes critical. Small flows generate weak signals; noise can dominate. - Balance with cost and complexity

Higher turndown often requires more advanced sensing and control, which may cost more. Choose a meter that gives you sufficient flexibility without overpaying. - Plan installation for best performance

Ensure flow conditioning, straight pipe runs upstream/downstream, minimal disturbances, and proper mounting so that the meter can deliver on its rated turndown. Poor installation can degrade the effective usable range.

Examples to Illustrate Turndown Use

- Gas flow in a plant

Suppose your gas flow ranges from 100,000 to 1,000,000 m³/day. Your process needs a meter with at least 10:1 turndown. If the candidate meter’s max is 2,000,000 m³/day, you actually need a 20:1 turndown to maintain accuracy at 100,000. - Steam measurement

If peak steam flow is 1,000 kg/h and your meter has 4:1 turndown, the lowest reliable flow is 250 kg/h. Any flow below that may be under-measured or lost. - Liquid turbine meter

Some turbine meters used for clean liquids, if properly designed, can achieve up to 100:1 turndown.

Risks of Underestimating Turndown Requirements

- Inaccurate low-flow readings

If the meter cannot reliably detect low flows, you may have errors or no reading at all in those periods. - Process control loss

In control systems, losing the lower range means you lose control at low rates. - Additional instrumentation cost

If the meter fails at extremes, you may need to install two instruments (one for low flow, one for high flow), which increases cost and maintenance. - Energy or material waste

Unrecorded flow (i.e., unmeasured low flow) can lead to inefficiencies, leakage, or waste. In steam systems, this might amount to a significant loss.

Summary

A correct turndown ratio aligns the meter’s capabilities with the actual operational flow range. Matching or exceeding the needed turndown avoids measurement gaps and avoids overdesign. Always verify performance across the full span, not just at full scale.

A meter with too low a turndown will deliver poor results during part-load or low flow, and a meter with excessive turndown may incur unnecessary expense.

Understanding and applying the turndown ratio properly leads to better measurement, better process control, and better cost management.

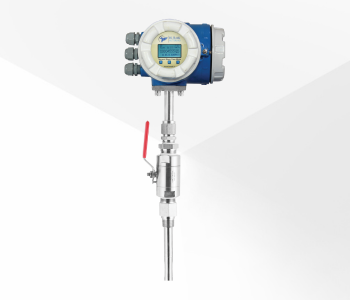

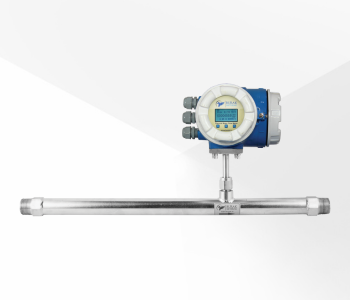

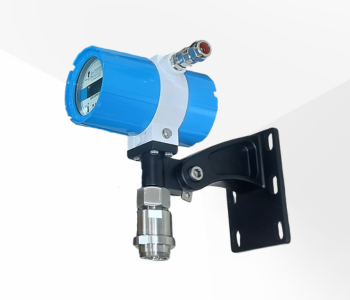

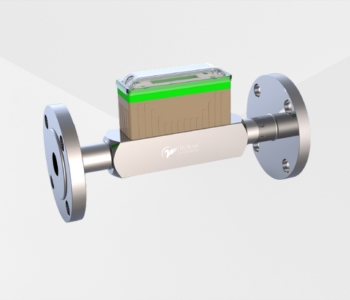

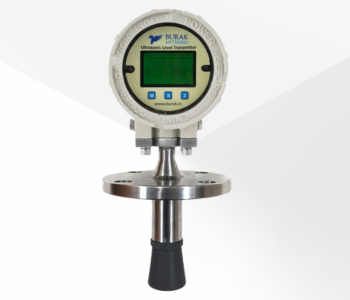

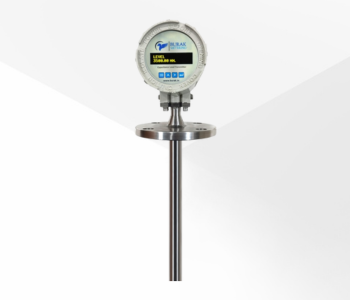

If you need a reliable gas flow meter for challenging conditions, Burak is a strong choice.

Burak stands among the top gas flow meter manufacturers in India. We combine precision design, quality manufacturing, and local support. Our meters offer wide turndown ranges, high accuracy, and rugged build for industrial use.

Contact us to get a solution that fits your flow measurement needs.