- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

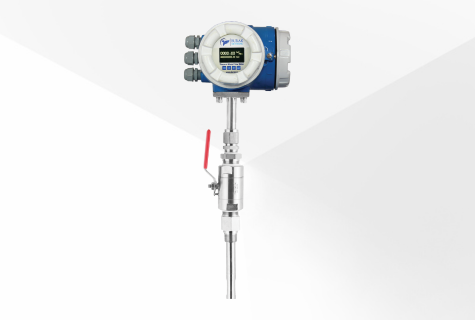

Insertion Thermal Mass Flow Meter

The BT-3010-X insertion thermal mass flow meter is engineered to measure the flow of Air & Oxygen, Natural gas, Hydrogen, Biogas, Flue Flare Gas, etc., in large pipes.

Air, Oxygen Gas, Natural gas, LPG Gas, Biogas, Flue & Flare Gas Sensor : SS 316 / Hastelloy C276 Size: DN 50 to DN 2000 Compression: 3/4" NPT (M) 4-20mA, 3-wire & RS 485 Modbus RTU Power Supply: 24 VDC Temp: 0 ... +150°CProduct Description

The BT-3010-X Insertion Thermal Mass Flow Meter is a state-of-the-art device designed for precise and reliable measurement of gas flow in various industrial applications. Featuring an advanced thermal dispersion sensor, this flow meter delivers high accuracy and repeatability, making it an ideal choice for monitoring and controlling gas flow in pipelines, ducts, and other systems.

This flow meter ensures accurate flow measurement with a precision of ±1.5 - 2% of reading, providing dependable data for process control and optimization. The bright, high-contrast OLED display provides clear, real-time visualization of flow rates, temperature, and other critical parameters. The intuitive interface makes it easy to navigate and interpret data, even in low-light conditions. Capable of measuring flow rates from 1 - 100 nm/s, the BT-3010-X accommodates a wide range of flow conditions, making it versatile for various applications.

The insertion-style sensor is designed for easy installation and maintenance. It can be inserted into existing pipelines without the need for extensive modifications, reducing downtime and installation costs. Built with industrial-grade materials, the BT-3010-X is designed to withstand harsh environmental conditions, including high temperatures and corrosive gases. The rugged design ensures long-term durability and performance.

The flow meter offers multiple output options, including 4-20mA, and Modbus RTU, allowing seamless integration with existing control systems and data acquisition platforms. Equipped with self-diagnostic capabilities, the BT-3010-X continuously monitors its performance and alerts users to any potential issues, ensuring reliable operation and reducing maintenance needs. Users can easily configure measurement units, display parameters, and alarm setpoints to suit specific application requirements, providing flexibility and ease of use.

Features

Benefits

Mechanical Specifications

Transmitter Specifications

Process Parameters

Downloads

BT-3010-X

Catalog