- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

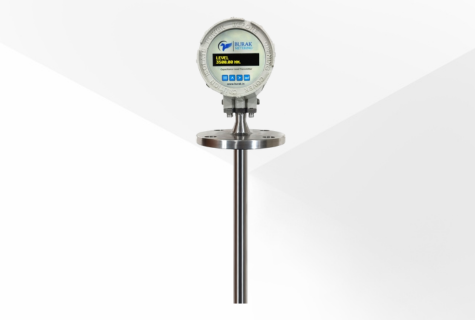

Capacitance Level Transmitter with 4-20mA, 3-wire & RS 485 Modbus

The CT-2000 Capacitance Level Transmitter provides accurate level measurement with a 4-20mA output (non-HART) and RS-485 Modbus communication. It is ideal for liquid and solid applications, ensuring reliable performance in industrial environments.

Water, Chemical, Diesel and low viscous liquids Display: OLED Display Range: 0 - 3 meters Probe Type Above 3 meters Rope type Measuring unit: mm, cm & meters Output: 4-20mA, 3-wire RS 485 Modbus RTU Mounting: Flange Ingress protection: IP 66 Design temp: -20 to 60°CProduct Description

The CT-2000 Capacitance Level Transmitter is a highly reliable and precise level measurement device designed for liquids, slurries, and bulk solids. It operates with a 4-20mA output (non-HART) and RS-485 Modbus communication, ensuring seamless integration into industrial automation systems. The integral display provides real-time level readings, enabling easy monitoring and configuration.

* Capacitive Sensing Technology for accurate and stable level measurement.

* 4-20mA Analog Output + RS-485 Modbus for digital communication and remote monitoring.

* Integral Digital Display for real-time level indication and easy setup.

* Robust Construction with an IP66 rated enclosure for harsh industrial environments.

* Flexible Mounting Options including threaded and flange connections.

* Suitable for Various Applications such as water treatment, chemicals, food processing, and bulk material storage.

* No Moving Parts, ensuring long-term durability and low maintenance.

The CT-2000 is ideal for industrial processes requiring accurate, maintenance-free, and cost-effective level measurement solutions.

Features

Benefits

Mechanical Specifications

Transmitter Specifications

Process Parameters

Downloads

CT-2000

Catalog