- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

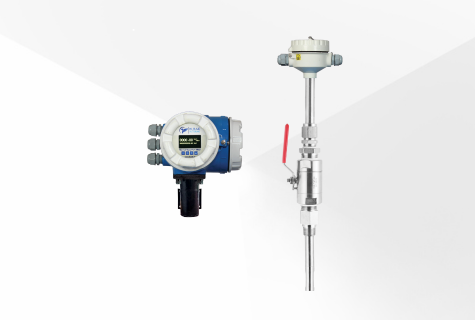

Insertion Thermal Mass Flow Meter

The BT-3010-XR insertion thermal mass flow meter is engineered to measure the flow of Air & Oxygen, Natural gas, Hydrogen, Biogas, Flue Flare Gas, etc., in large pipes.

Air, Oxygen Gas, Natural gas, LPG Gas, Biogas, Flue & Flare Gas Sensor : SS 316 / Hastelloy C276 Display: Remote Mount Size: DN 50 to DN 2000 4-20mA, 3-wire & RS 485 Modbus RTU Power Supply: 24 VDC Temp: 0 ... +150°C & 350°C optionalProduct Description

The BT-3010-XR Insertion Thermal Mass Flow Meter is engineered for precise and reliable gas flow measurement in various industrial applications, particularly where high temperatures are prevalent. This advanced flow meter features a thermal dispersion sensor that delivers high accuracy and repeatability, ensuring dependable data for process control and optimization.

A key feature of the BT-3010-XR is its remote display, designed for easy viewing and accessibility. This allows operators to monitor flow rates, temperature, and other critical parameters from a convenient location, enhancing usability and safety. The remote display provides clear, real-time visualization, making it easy to navigate and interpret data even in challenging environments.

The BT-3010-XR is capable of handling high-temperature applications, making it suitable for processes involving extreme heat. Its robust construction, using industrial-grade materials, ensures durability and reliable performance under harsh conditions, including exposure to corrosive gases and elevated temperatures.

This flow meter offers versatile output options, including 4-20mA, and Modbus RTU, facilitating seamless integration with existing control systems and data acquisition platforms. It also features self-diagnostic capabilities, continuously monitoring its performance and alerting users to potential issues, thereby reducing maintenance needs and ensuring reliable operation.

The BT-3010-XR Insertion Thermal Mass Flow Meter with Remote Display is an ideal solution for accurate and efficient gas flow measurement in high-temperature and demanding industrial environments. Its advanced features, robust design, and user-friendly remote interface deliver exceptional performance and reliability, supporting optimal process control and efficiency.

Features

Benefits

Mechanical Specifications

Transmitter Specifications

Process Parameters

Downloads

BT-3010-XR

Catalog