Working Principle of hydrostatic level transmitter

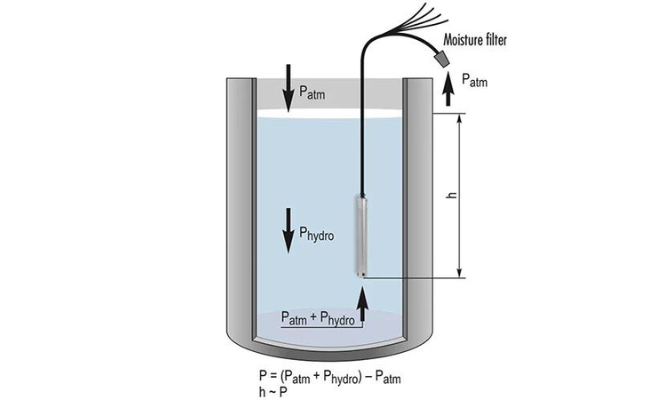

The working principle of a hydrostatic level transmitter hinges on the fundamental concept of hydrostatic pressure generated by the depth of a liquid.

Pressure Sensing: A hydrostatic level transmitter typically incorporates a pressure sensor placed at the bottom of a tank or container containing the liquid whose level needs measurement.

Hydrostatic Pressure: As the liquid level changes within the tank, the pressure exerted by the column of liquid above the sensor varies. This pressure is directly proportional to the depth of the liquid according to the hydrostatic pressure formula—pressure equals density multiplied by gravitational acceleration multiplied by height.

Pressure Measurement: The sensor accurately detects the pressure exerted by the liquid above it. This pressure reading is directly related to the depth of the liquid, providing a reliable indication of the substance's level within the tank.

Conversion to Level Measurement: The hydrostatic level transmitter translates the pressure reading obtained from the sensor into an accurate representation of the substance's level within the container. This conversion is usually achieved through calibration and mathematical algorithms that correlate pressure to level.

Data Transmission: The level measurement data derived from the pressure reading is transmitted to a control system or displayed in real time. This enables continuous monitoring and management of the substance's level within the tank.

Hydrostatic level transmitters are effective for measuring the level of compatible liquids in various industries. They rely on direct contact between the liquid and the sensor, providing reliable and accurate measurements. Their application spans across industries such as wastewater treatment, oil and gas, chemical processing, and more, where precise and continuous level monitoring is crucial for operational efficiency and safety.