- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

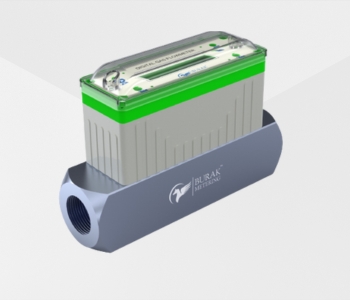

Gas Flow Meter with Screwed Mount

The BY-200-V inline thermal mass flow meter with a Screwed connection is designed to measure the flow of compressed air, blower air, argon gas, nitrogen, etc., in small pipes ranging from ½” up to 2” in size.

For Compressed Air, Nitrogen, Argon, PNG, LPG Size: DN 4 to DN 50 Thread: BSP, NPT, etc 4-20mA 3-wire, RS 485 Modbus Body: Aluminium , SS 304, SS 316 Enclosure: ABS Weatherproof Power Supply: 24 VDC Temp: 0 ... +80°CProduct Description

BY-200-V Gas flow meter with screwed connections, available in sizes from 1/4" up to 2" and featuring various thread connections, is a cost-effective and versatile solution for measuring gas flow. This model is built with a durable aluminum body, offering a combination of strength, lightweight construction, and corrosion resistance. These attributes make it ideal for a wide range of industrial applications where reliable and accurate gas flow measurement is essential.

The electronic enclosure is made from ABS (Acrylonitrile Butadiene Styrene) plastic, which is known for its robustness and impact resistance. This material ensures that the sensitive electronic components housed within are well-protected from environmental factors and potential physical damage. The use of ABS plastic also helps maintain the overall lightweight nature of the device, making it easier to handle and install.

The screwed connection design, which accommodates different thread sizes from 1/4" to 2", enhances the meter's flexibility and ease of integration into existing systems. This type of connection is particularly advantageous for applications requiring frequent maintenance or adjustments, as it allows for quick and secure assembly and disassembly. The variety of thread connections further increases the adaptability of the meter, enabling it to be used in diverse settings and with different piping standards.

Overall, this thermal mass flow meter with its aluminum body and ABS plastic electronic enclosure represents an economical yet reliable choice for gas flow measurement. It combines durability, ease of use, and versatility, making it a preferred option for industries seeking an efficient and affordable solution to their gas flow monitoring needs.

Features

Benefits

Mechanical Specifications

Transmitter Specifications

Process Parameters

Downloads

BY-200-V

Catalog