- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Types of Fluid and Fluid Flow in Industry

Fluids play a vital role in modern industries. From manufacturing and energy production to pharmaceuticals and food processing, fluids drive essential operations. Understanding different fluids and how they move is crucial for maintaining system performance and safety.

This guide explains industrial fluids and their movement patterns, known as fluid flow. It also outlines common flow types and their importance in real-world applications.

What is a Fluid?

A fluid is any substance that can flow and does not have a fixed shape. It can be a liquid, gas, or a mixture of both. Unlike solids, fluids take the shape of their container.

In industries, fluids are used for many purposes:

- Cooling machinery

- Transporting materials

- Generating power

- Lubricating moving parts

- Controlling chemical reactions

Examples: Water, Oil, Steam, Compressed air, and Hydraulic fluids.

Types of Industrial Fluids

Different industries handle different fluids based on process needs. Below are common categories:

1. Liquids

Liquids are the most widely used industrial fluids. They maintain a fixed volume but adapt to any container shape.

Examples:

- Water – for cooling systems, boilers, and cleaning.

- Oils – for lubrication and hydraulic systems.

- Chemicals – for production processes like refining or mixing.

- Food-grade liquids – such as milk, juice, or syrup.

2. Gases

Gases expand freely and fill any available space. They are essential in heating, combustion, and pressurized systems.

Common industrial gases:

- Air for pneumatic systems

- Steam for turbines

- Oxygen for steelmaking

- Natural gas for heating and energy generation

3. Two-Phase Fluids

Two-phase fluids are mixtures of liquids and gases. They occur naturally or through industrial processes.

Examples:

- Steam-water mixtures in power plants

- Refrigerants in cooling systems

- Gas-liquid flows in chemical reactors

4. Specialized Fluids

Some industries rely on engineered fluids for specific tasks:

- Hydraulic fluids for power transmission

- Coolants for temperature control

- Solvents for cleaning or dissolving materials

- Cryogenic fluids like liquid nitrogen for extreme cooling

What is Fluid Flow?

Fluid flow refers to the movement of fluids through pipes, channels, or open systems. It depends on factors such as pressure, temperature, and fluid properties like density and viscosity.

Studying fluid flow helps industries:

- Optimize energy use

- Reduce equipment wear

- Improve product quality

- Maintain safety standards

Types of Fluid Flow

Fluid movement is classified into different flow patterns. Each type has specific features and industrial uses.

1. Laminar Flow

Laminar flow is smooth and orderly. Particles move in parallel layers with minimal mixing.

Key characteristics of laminar flow:

- Slow movement

- Low energy loss

- Predictable behavior

It usually occurs in systems with small pipes or highly viscous fluids like oil.

Applications:

- Pharmaceutical manufacturing

- Food processing

- Chemical mixing

Example: Oil flowing through a thin tube at steady speed.

2. Turbulent Flow

Turbulent flow is chaotic and irregular. Particles swirl and mix rapidly.

Key characteristics of turbulent flow:

- High velocity

- Increased energy loss

- Unpredictable motion

It commonly appears in large pipelines or where speed is high.

Applications:

- Water distribution networks

- Gas pipelines

- Power plant cooling systems

Example: River water rushing over rocks.

3. Transitional Flow

Transitional flow exists between laminar and turbulent flow. Conditions fluctuate, causing sections of both types to appear.

Applications of transitional flow:

- Medium-sized industrial pipelines

- Systems that handle variable speeds or pressures

Example: Water slowly accelerating in a pump line before reaching full turbulence.

4. Steady Flow

In steady flow, fluid properties like speed and pressure stay constant at every point over time.

This stability makes system monitoring easier.

Applications of steady flow:

- Continuous production lines

- Cooling circuits in machinery

Example: Consistent water flow in a controlled irrigation system.

5. Unsteady Flow

Unsteady flow shows changes in speed, direction, or pressure over time.

This variation can be intentional or due to system issues.

Applications of unsteady flow:

- Pulsating pumps

- Batch chemical processes

- Fluctuating power generation

Example: Water hammer effect in pipelines.

6. Compressible Flow

Compressible flow occurs when fluid density changes significantly due to pressure or temperature variations. It mainly involves gases.

Applications of compressible flow :

- Jet engines

- Gas turbines

- High-pressure steam systems

Example: Air speeding through a compressor blade.

7. Incompressible Flow

In incompressible flow, fluid density remains constant. Liquids generally behave this way under normal conditions.

Applications of incompressible flow:

- Hydraulic presses

- Cooling towers

- Water distribution

Example: Water flowing steadily through a residential pipe.

8. Single-Phase Flow

Single-phase flow involves a fluid in one consistent state—only liquid or only gas.

Applications:

- Domestic water supply

- Pure air systems

- Oil pipelines

Example: Clean water moving through a municipal pipeline.

9. Multi-Phase Flow

Multi-phase flow involves multiple states or materials, such as liquid-gas, solid-liquid, or solid-gas mixtures.

Applications:

- Oil and gas extraction

- Chemical processing

- Waste treatment systems

Example: Crude oil mixed with natural gas during transportation.

Industrial Importance of Fluid Flow

Efficient fluid flow keeps production smooth and costs controlled. Poor flow management can lead to:

- Energy waste

- Equipment damage

- Safety hazards

- Product defects

Correct flow type selection improves system flowmeter performance and minimizes downtime.

Factors Affecting Fluid Flow

Several factors influence how fluids move in industrial systems:

- Pressure Differences – Greater pressure increases fluid speed.

- Pipe Design – Shape and diameter affect flow behavior.

- Fluid Properties – Viscosity, density, and temperature matter.

- Flow Velocity – Higher velocity increases turbulence.

- Surface Roughness – Rough pipe interiors increase resistance.

Common Fluid Flow Equipment

Industries use specialized tools to manage and measure fluid flow.

- Pumps – Move fluids through systems.

- Valves – Control direction and rate.

- Flow meters – Measure speed and volume.

- Compressors – Pressurize gases.

- Filters – Remove impurities.

Flow Measurement Methods

Monitoring flow helps maintain efficiency and safety. Common flow measurement techniques include:

- Differential Pressure Meters – Use pressure changes to calculate flow rate.

- Electromagnetic Flow Meters – Work with conductive fluids like water.

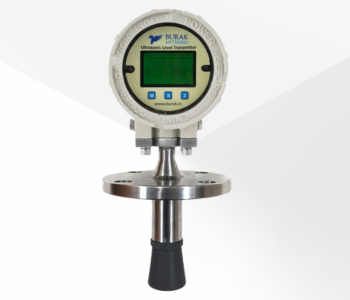

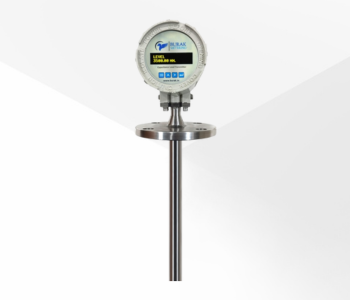

- Ultrasonic Flow Meters – Send sound waves through flowing fluid.

- Turbine Flow Meters – Use spinning blades to measure speed.

Safety Considerations

Improper flow control can cause leaks, explosions, or contamination. Regular maintenance and monitoring are essential to prevent accidents.

Industrial teams should:

- Inspect equipment regularly

- Calibrate meters and sensors

- Train workers on proper handling

- Use correct materials for pipes and fittings

Conclusion

Fluids are central to industrial systems, whether in liquid, gas, or mixed forms. Understanding different flow types, such as laminar, turbulent, transitional, steady, unsteady, compressible, and incompressible. Helps engineers design efficient processes.

By managing fluid flow correctly, industries achieve safer operations, reduce energy use, and maintain consistent product quality.

Clear knowledge of fluid types and behavior strengthens production systems, improves output, and supports long-term operational success.

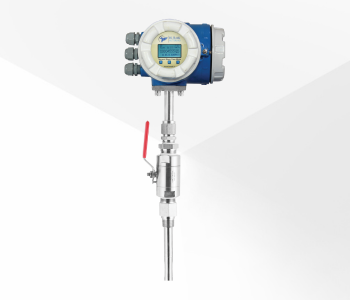

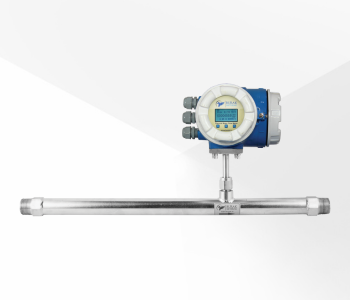

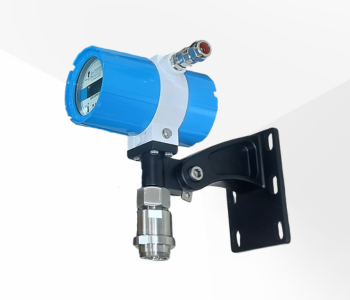

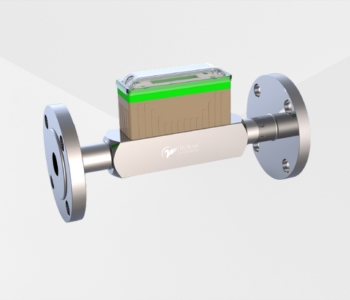

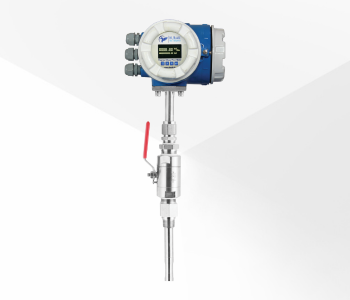

At Burak, we specialize in precision flow measurement devices that help industries achieve accurate monitoring and efficient operations. As a leading flow meter manufacturer in India, we provide solutions for liquids, gases, and multi-phase fluids across various industries.

Our range includes thermal mass flow meters, electromagnetic, ultrasonic, turbine, and differential pressure flow meters, all designed to deliver dependable performance and long-term reliability.

Partner with Burak to enhance process safety, optimize energy use, and reduce maintenance costs.

Contact us today to discuss your requirements and learn how our expertise can support your industrial systems.