Phone

Phone

A flow meter is a device used to measure the flow rate of liquids or gases in a pipe. It helps determine how much fluid passes through at any given time, and it measures the volume or mass of a gas or liquid.

In different industries, flow meters are called flow gauges, flow indicators, liquid meters, flow rate sensors, etc. All of them, however, measure flow.

With the best flow meters, fluid measurement can be more precise, accurate, and efficient. It is not uncommon for industrial applications to require precise quantity calculations to be made. Nonetheless, a vineyard may only need a 5% to 10% degree of accuracy if the goal is to measure water flow to the vineyard.

It is important to note that no “universal” flow meter can be used for all applications. So you must be aware of the critical and technical specifications before you purchase one.

This article will guide you through everything you need to know about flow meters, helping you choose the best one for your specific needs.

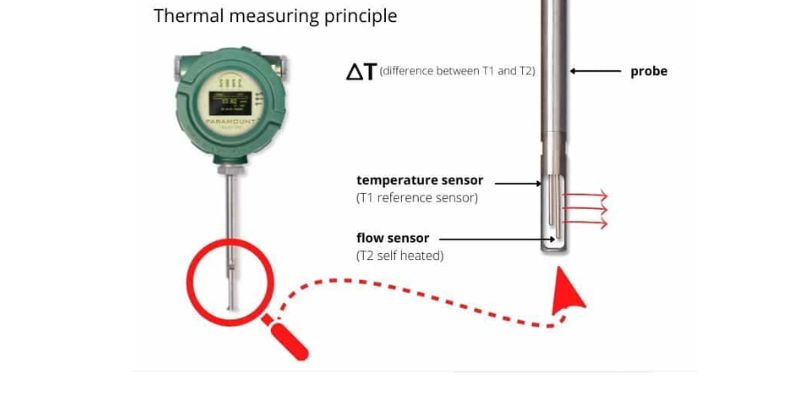

A thermal mass flow meter uses heat to determine the speed at which a gas or liquid is moving. It has a tiny heater inside the pipe. The heater cools when the gas or liquid passes over it, and it cools quickly when the flow is fast. In this way, it determines how quickly the gas or liquid is flowing by measuring the amount of heat lost.

Principle: Heat transfer

Working: The thermal mass flowmeter measures gas mass flow by monitoring how much heat is lost as the gas flows through the pipe. It essentially consists of two temperature sensors and a heater element.

One sensor measures fluid temperature before it passes the heater, and the other measures the temperature after. When gas flows over the heater, it absorbs heat. The quicker it moves, the more heat it will carry away.

Measurement of the differential temperature before and after heating provides the flow meter with the data to calculate the mass flow rate of a gas.

Applications: Ideal for measuring the flow of gases, particularly in HVAC (Heating, Ventilation, and Air Conditioning) systems and industrial applications.

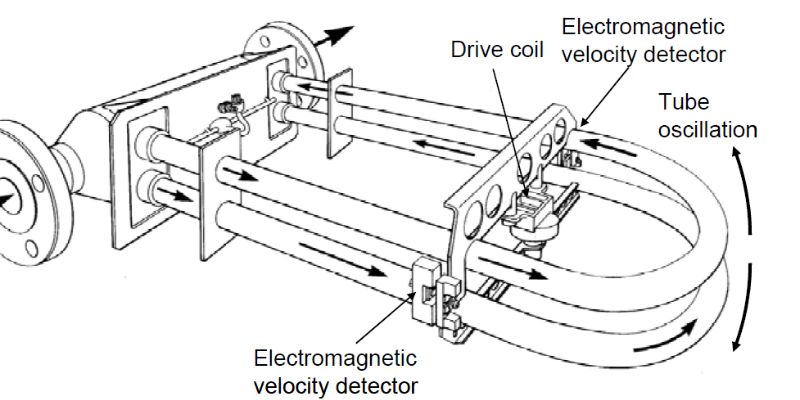

A Coriolis mass flow meter operates on the principle of the Coriolis force, named after French scientist Gaspard-Gustave de Coriolis, who discovered it. This flow meter has two pipes in its structure, and it measures how much liquid or gas is flowing by feeling how it twists the pipe as it moves. The flow meter has vibrating tubes inside it. The tubes twist slightly as the liquid or gas passes through them. The more liquid or gas flows, the more it twists.

Principle: Coriolis effect

Working: The Coriolis mass flowmeter utilizes the Coriolis force. Inside, the meter contains tubes that are vibrating at a fixed frequency.

As fluid, gas, and liquid pass through the tubes, their mass flow induces a slight twist or bend in the tubes, changing their vibration. This twisting is due to the Coriolis force acting on the fluid as it moves through the vibrating tubes.

The degree of twisting is directly proportional to the mass flow rate. Sensors measure the phase shift (the change in vibration) to calculate the mass flow.

Applications: Commonly used in oil, gas, and chemical industries for precise mass flow measurement.

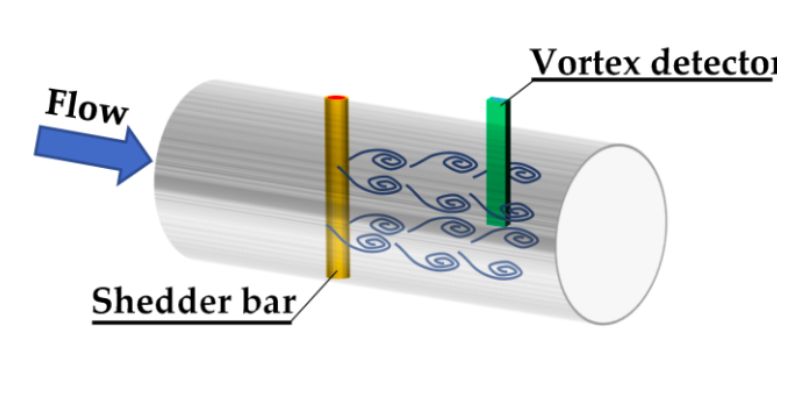

A vortex flow meter works by watching the swirls made by liquid or gas as it flows through a pipe. A little object in the center of the pipe causes the liquid to spin and form tiny vortices, or whirlpools. The flow meter measures the number of swirls to determine how much liquid or gas is flowing.

Principle: Vortex shedding.

Working: The vortex flowmeter measures the flow rate by observing the vortices (swirls) created as the fluid flows inside the pipe.

As the fluid flows around this object, alternating vortices are generated on each side of the object. These vortices form a repeating pattern of low and high-pressure zones, causing vibrations that are detected by a sensor.

The frequency of the vortex is directly proportional to the flow rate, which allows the meter to calculate the flow of the fluid.

Applications: Suitable for gas, liquid, and steam in water treatment, chemical processing, and HVAC systems, among other sectors.

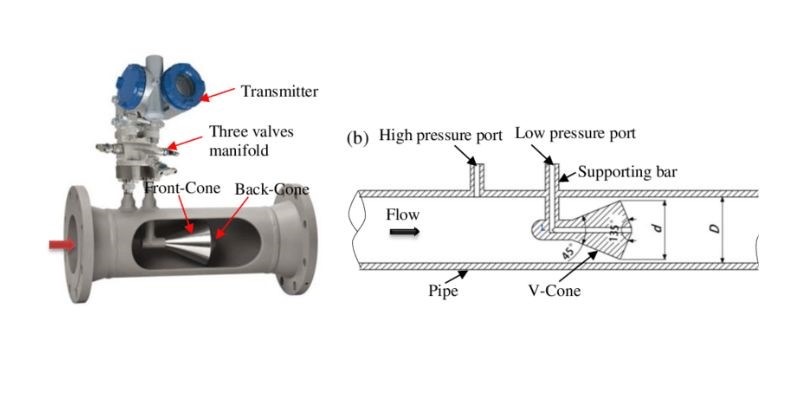

A cone-shaped item is located inside the pipe of a cone flow meter. When liquid or gas passes through the cone, the pressure changes. This change in pressure is measured by the flow meter to determine the volume of liquid or gas passing through.

Principle: Differential pressure

Working: The cone flowmeter operates by creating a differential pressure drop as the fluid flows through a cone-shaped obstruction inside the pipe. The fluid's velocity increases and its pressure drops as it moves past the cone's narrowest point. Then the sensors placed before and after the cone measure this pressure differential.

Applications: Frequently used in high-pressure settings for steam, gas, and oil flow measurements.

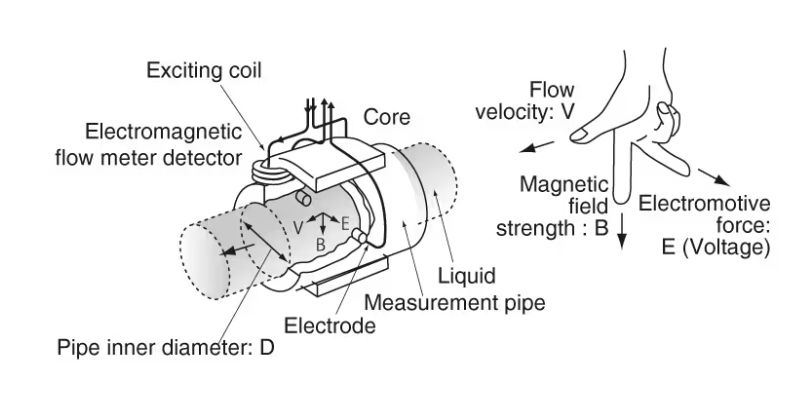

Magnets are used in electromagnetic flowmeters to measure flow. A little electric signal is produced when a liquid that conducts electricity (such as water) passes through the magnetic field. The signal gets stronger as the liquid flows faster. This signal is read by the flow meter to determine the flow.

Principle: Faraday’s Law of Electromagnetic Induction

Working: An electromagnetic flow meter is based upon Faraday's Law, wherein a voltage is induced on a conductive liquid moving perpendicularly through a magnetic field.

In the electromagnetic flow meter shown here, electrodes are mounted on the walls of the pipe, and a magnetic field is imposed across the pipe. The water or any other conductive liquid, according to Faraday's law of electromagnetic induction, will induce a voltage proportional to the velocity of flow while passing through the magnetic field.

The faster the liquid moves, the higher the voltage. This voltage is measured and converted into flow.

Applications: Ideal for conductive liquids, such as water and wastewater, which are frequently utilized in municipal water systems.

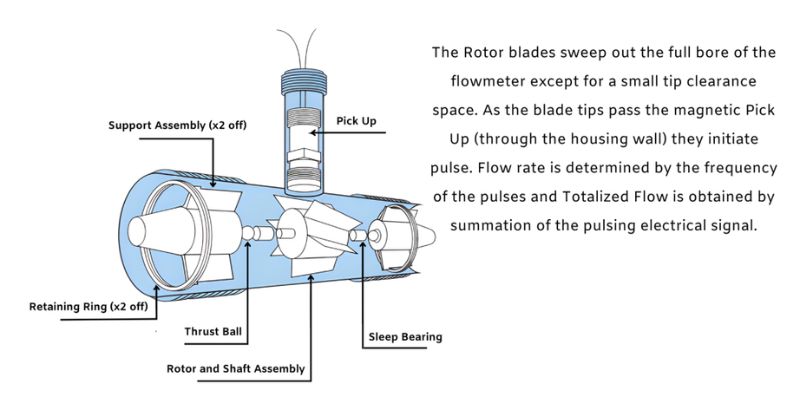

A tiny fan, or turbine, is located inside the pipe of a turbine flow meter. The fan rotates when liquid or gas flows. The fan spins more quickly the faster the flow. To determine the flow rate, the flow meter counts the number of times the fan rotates.

Principle: Mechanical rotation

Working: A turbine flowmeter has a small rotor or fan that is installed inside the pipe. Thus, when fluid flows through the pipe, it touches the blades of the turbine, causing it to rotate.

The rotation rate is proportional to the flow velocity of the fluid. Sensors detect the rotational speed of the turbine; these data are utilized to calculate the flow rate. The faster the turbine spins, the higher the flow rate.

Application: Extensively utilized in sectors requiring the measurement of liquids and gases, such as chemical processing, water distribution, and oil and gas.

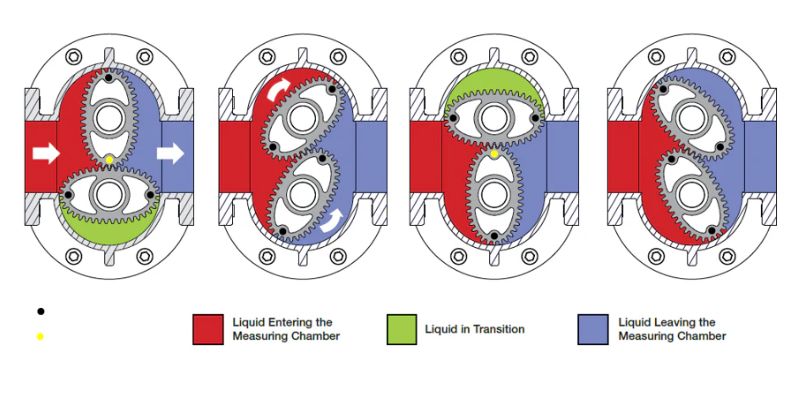

There are two oval-shaped gears inside an oval gear flow meter. The movement of liquid or gas causes these gears to rotate. To determine how much liquid is flowing, the flow meter counts the number of times the gears revolve.

Principle: Positive displacement

Working: The oval gear flow meter consists of two oval-shaped gears that, when the fluid passes through the meter, rotate.

The liquid or gas pushes these gears to rotate within the chamber. Each rotation passes a fixed volume of fluid through the meter. It is the meter that counts the number of gear rotations and calculates the volume of fluid that has been passed through the system. Oval gear flow meters are highly accurate and, thus, very reliable.

Application: Frequently employed in sectors requiring accurate volumetric measurements, such as chemical manufacturing, food processing, and oil and gas.

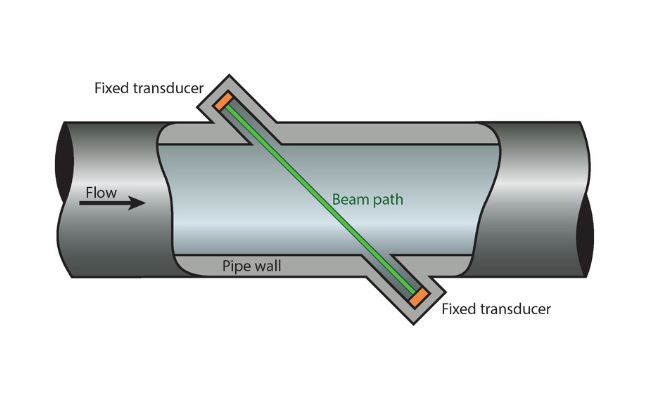

Ultrasonic flowmeters measure flow rates and volumes using sound waves, without needing any direct contact. Their external installation simplifies setup and saves time. In contrast, other flow devices often require cutting into pipes, which can be hazardous.

Principle: Transit-Time

Working: The transducer measures flow rate and can be positioned either parallel or angled to the pipe. Two ultrasonic transmitters send short pulses, which are captured by receivers as they travel through the fluid.

The primary transmitter sends sound waves in the direction of flow, amplifying the signal with the fluid's speed. The secondary transmitter sends waves against the flow, causing the signal to weaken due to the opposing direction.

Applications: Oil and Gas, Power generation, flare gas monitoring, etc.

Orifice, Venturi wedge, Rota meter, etc, are the different types of flow meters.

Flow meters provide a very accurate reading of the flow rate of liquids or gases. This accuracy is crucial for industries in which even slight changes may affect quality, for example, in chemical manufacturing or water treatment processes.

It is achieved by continuously observing the flow of fluids. Flowmeters enable companies to detect inefficiencies in advance, which may come in the form of leaks or blockage, and save precious time, energy, and resources.

The use of flow meters minimizes waste, as it ensures only the needed amount of the fluid is used. This can mean huge savings in industries such as oil and gas or food processing.

Flow meters control the flow rate of hazardous fluids, such as chemicals or gases, and help to reduce or stop accidents by not allowing the flow rate to exceed the prescribed limits.

Most industries have strict guidelines and regulations concerning the usage of fluids and gases. Flow meters can help to meet these standards.

Chemical Industry: Flow meters are used in chemical plants to control the flow of liquids and gases.

Pulp and Paper Industry: Flow meters maintain the required quantity of water and chemicals necessary for processing the wood pulp into paper.

Power Plants: The flow meters are being used in power plants to measure the water, steam flow, and fuel flow.

Food Processing: Flow meters are used in food processing industries to measure the flow of liquids such as water, milk, juice, or oils within the flow in food factories.

Pharmaceutical Industry: During the production of drugs, flowmeters control the flow of substances to maintain accuracy and safety.

Textile Industry: In the manufacture of fabrics, flow meters measure water, dyes, and chemicals.

Water and Wastewater Treatment: Flow meters are installed in piping and vessels to ensure adequate flow of clean water and treated wastewater, eliminating overuse or contamination.

Petroleum Industry: Flowmeters measure the flow of crude oil, natural gas, and refined products in pipelines and storage tanks.

Steel Industry: A steel mill uses a flow meter to gauge how much gas has been used to make a product

Renewable Energy, Automotive Industry, Aeronautics Industry, etc, are the various industries that use flow meters to ensure accuracy, enhance efficiency, and minimize waste.

Start by defining your flow measurement requirements. Identify the fluid type (liquid or gas), expected flow rate range, and operating conditions such as temperature and pressure. These details help determine which flow meter technology suits your application.

There are several types of flowmeters available, each with specific use cases:

Understanding how each technology works helps you select the right flow meter type for your process.

Accuracy is critical in applications that require precise control or regulatory compliance. Choose a high-accuracy flow meter that matches your required measurement tolerance and offers consistent repeatability for reliable data.

Check if the flow meter materials are compatible with the fluid being measured. Corrosive, abrasive, or particulate-laden fluids can damage some meters. Select a flow meter designed to handle the chemical properties and flow characteristics of your specific fluid.

Consider the ease of installation and maintenance requirements. Some flow meters need special positioning, straight pipe runs, or regular calibration. Choosing a low-maintenance flow meter can reduce downtime and lower operational costs.

Account for the operating environment. Look at temperature ranges, humidity levels, and exposure to dust, moisture, or chemicals. Select a flow meter built to handle these environmental factors without losing accuracy or durability.

Factor in both the initial cost and the lifecycle cost. A cheaper meter may have higher maintenance needs, while a more expensive model may offer better long-term value through reliability and reduced servicing. Balance your flow meter budget with total ownership cost.

Ensure the flow meter comes with proper calibration and complies with industry certifications. Certified meters meet performance standards and help ensure regulatory compliance and quality assurance.

Flowmeters are essential to many different industries because they provide precise measurement, increased productivity, and enhanced process control.

Whether you're measuring gas, water, or more complicated fluids, it's critical to select the appropriate flow meter depending on your unique requirements.

There are several types of flow meters available. An appropriate flow meter can improve safety and cut waste, among other things, greatly benefiting your business.

Are you looking for the ideal flow meter for your requirements?

You can explore Burak Metering's products, one of the leading manufacturers of flow meters, or you can get in touch with our team for expert guidance!