- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Gas Flowmeter Certifications Required for Indian Manufacturers

TL;DR

- Indian flowmeter manufacturing depends on defined certifications and standards.

- ISO, BIS, OIML, and PESO rules control quality, safety, and accuracy.

Flowmeter manufacturing in India operates under defined technical and regulatory frameworks.

These frameworks control product safety, measurement accuracy, and production quality.

Certifications and standards guide manufacturers, buyers, inspectors, and regulators.

Indian flow meter manufacturers must align with national and international benchmarks to compete in domestic and export markets.

Gas flow meter manufacturers in India face added scrutiny due to pressure systems, combustible media, and custody transfer use.

Burak aligns its manufacturing, testing, and documentation with recognized standards to support compliance, reliability, and long-term field performance.

Importance of Certifications in Flow Meter Manufacturing

Certifications confirm that a flow meter meets specific technical rules. Standards define testing methods, material limits, accuracy classes, and operational boundaries.

Regulators rely on certified instruments for trade measurement and safety enforcement.

End users rely on certified products for process control and billing integrity.

Indian gas flow meter manufacturers must demonstrate conformity through audits, testing records, and calibration traceability.

Burak integrates certification requirements at design, machining, assembly, and final inspection stages.

ISO Standards Followed by Indian Manufacturers

ISO 9001: Quality Management Systems

ISO 9001 governs quality management practices. This standard controls document flow, supplier evaluation, inspection plans, and corrective action handling. Flow meter manufacturers use ISO 9001 to maintain repeatable production outcomes.

Burak applies ISO 9001 controls across casting, machining, rotor balancing, and final meter assembly to maintain dimensional and performance consistency.

ISO 14001: Environmental Management Systems

ISO 14001 regulates environmental impact. It covers waste handling, emissions control, and resource use. Flow meter manufacturing involves machining fluids, metal scrap, and surface treatment chemicals. Compliance supports responsible factory operations.

Burak applies environmental controls that align with ISO 14001 guidelines within its production facilities.

ISO 45001: Occupational Health and Safety

ISO 45001 addresses worker safety. Pressure testing, welding, and mechanical handling present risks in flow meter plants. This standard requires hazard identification and risk control.

Burak follows structured safety procedures across testing bays, calibration labs, and assembly zones.

Schedule flow meter testing services with traceable calibration and documented performance results.

Indian Regulatory Standards for Flow Meters

Bureau of Indian Standards (BIS)

BIS develops Indian Standards (IS) for industrial instruments. Flow meters used in regulated sectors may require conformity to relevant IS specifications.

BIS standards define material grades, dimensional tolerances, and test conditions. Manufacturers supplying government or public-sector projects often require BIS-aligned products.

Burak designs gas flow meters to meet applicable Indian Standards where mandated.

Legal Metrology Act Compliance

The Legal Metrology Act governs measurement devices used for trade. Gas flow meters used for billing must satisfy accuracy and repeatability criteria. Authorities may require model approval and periodic verification.

Burak supports legal metrology requirements through calibrated testing and traceable documentation.

Request certified gas flow meters engineered for stable measurement across industrial applications.

Calibration and Testing Standards

NABL-Traceable Calibration

Calibration validates measurement accuracy. Indian manufacturers rely on NABL-accredited laboratories for traceability to national standards. Gas flow meters undergo flow testing across defined ranges. Calibration certificates confirm performance under controlled conditions.

Burak performs flow testing using NABL-traceable references to support accuracy claims and audit readiness.

ISO 17025 Testing Framework

ISO 17025 defines testing and calibration competence. Laboratories following this framework apply controlled procedures, validated methods, and uncertainty calculations.

International Gas Flow Meter Standards Used in India

OIML R 137

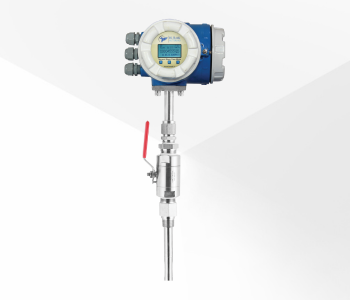

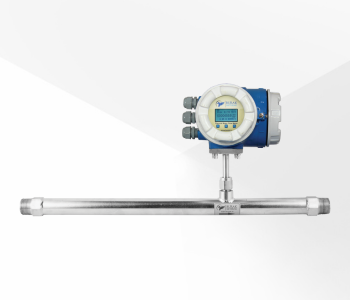

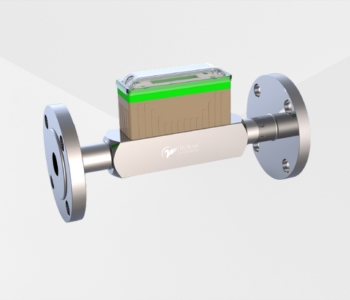

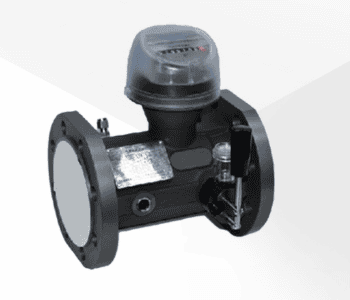

OIML R 137 applies to gas meters used in custody transfer and industrial measurement. It defines accuracy classes, pressure loss limits, and endurance tests. Many Indian gas utilities and export projects specify OIML-compliant meters. Burak manufactures turbine gas flow meters aligned with OIML R 137 requirements for regulated gas measurement.

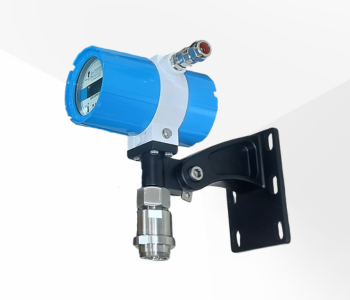

ATEX and IECEx for Hazardous Areas

Gas flow meters installed in explosive environments require certified components. ATEX and IECEx standards regulate equipment used in hazardous zones. These standards define temperature classes, enclosure protection, and ignition risk control.

Burak supplies gas flow meters suitable for hazardous locations through compliant design and certified accessories.

Partner with Burak for the supply, testing, and installation of gas flow meters across India.

Pressure Equipment and Safety Compliance

PESO Approval

The Petroleum and Explosives Safety Organisation (PESO) regulates pressure vessels and gas systems in India. Flow meters used in petroleum and natural gas systems must meet PESO rules where applicable. PESO approval focuses on material strength, pressure rating, and safety margins.

Burak supports PESO-related requirements through material certification and pressure testing records.

Material and Manufacturing Controls

Standards also govern raw material selection. Gas flow meters require stable alloys that resist corrosion and pressure fatigue. Material test certificates confirm chemical composition and mechanical properties. Dimensional inspection verifies housing and rotor geometry.

Burak applies controlled sourcing and inspection protocols aligned with standards-based manufacturing expectations.

Documentation and Traceability Requirements

Certifications demand structured documentation. Records include drawings, test results, calibration data, and inspection reports. Traceability links each meter to its production batch and test history. This structure supports audits and after-sales support.

Burak maintains detailed documentation for every gas flow meter supplied to Indian and international clients.

Contact us to upgrade your gas measurement systems using factory-tested flow meters with compliance-ready documentation.

Role of Standards in Market Acceptance

Standards support buyer confidence. EPC contractors, utilities, and industrial operators specify certified meters in tender documents. Compliance reduces project risk and inspection delays. Export markets also demand conformity to international norms.

Burak’s adherence to recognized certifications strengthens acceptance across energy, petrochemical, and infrastructure sectors.

Future Direction of Indian Flow Meter Standards

Indian flow meter manufacturing continues to align with global practices. Increased gas infrastructure expansion drives stricter accuracy and safety expectations. Digital monitoring and automated calibration systems gain relevance.

Certification frameworks will continue to guide product development and approval.

Burak invests in standards-aligned upgrades to meet evolving market and regulatory needs.

Why Burak Leads in Certified Gas Flow Meter Manufacturing

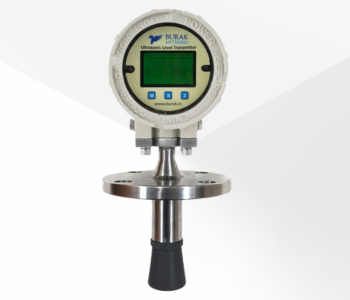

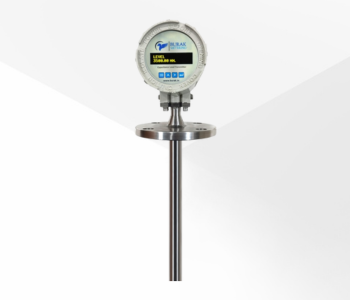

Burak operates as one of the established gas flow meter manufacturers in India. The company integrates certification requirements into design validation, machining control, and final testing.

Burak supplies turbine gas flow meters that align with ISO, OIML, PESO, and hazardous-area standards.

This structured approach supports reliability, regulatory acceptance, and long service life across Indian gas networks.

Contact Us

Burak supports industrial clients, gas utilities, and EPC firms with certified gas flow meter solutions across India.

The company combines controlled manufacturing, documented testing, and standards-aligned designs to support demanding applications.

Burak stands as a preferred choice for organizations seeking dependable gas flow meters backed by technical compliance and sector experience.

Contact Burak to discuss project requirements, certification needs, or product selection support.