Phone

Phone

Saeed Lanjekar

12 Jun, 2025

6 Minutes

Flow meters play a vital role in measuring and monitoring the flow of liquids, gases, and steam across various industries. Selecting the right flow meter depends on factors such as fluid type, operating conditions, required accuracy, and industry-specific needs.

As a leading flow meter manufacturer, Burak Metering provides high-quality flow measurement solutions for diverse industrial applications. In this guide, we will explore the most common types of flow meters and their key uses in different sectors.

Differential pressure flow meters operate by creating a pressure drop across a restriction (such as an orifice plate or venturi tube) and calculating flow rate based on the pressure difference.

Oil & Gas: Used in pipelines for crude oil and natural gas measurement.

Water Treatment: Monitors flow in treatment plants and distribution systems.

Power Plants: Measures steam flow in boilers and turbines.

Chemical Processing: Suitable for non-corrosive liquid and gas flow monitoring.

Burak Metering’s Expertise: Our DP flow meters are designed for reliability in harsh industrial environments.

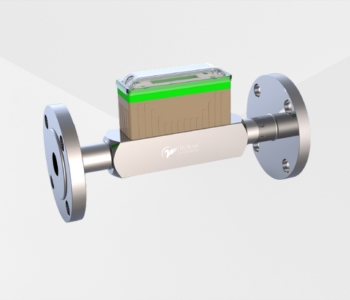

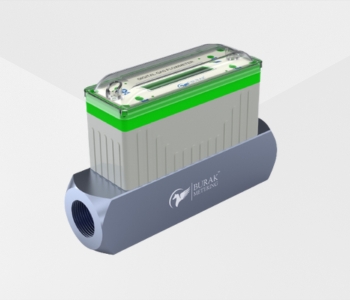

Ultrasonic flow meters measure flow velocity using sound waves, with two main types: transit-time (for clean liquids) and Doppler (for slurries or dirty fluids).

Water & Wastewater: Provides accurate flow measurement without pipe intrusion.

HVAC Systems: Monitors chilled and hot water flow in heating/cooling systems.

Petrochemicals: Measures hydrocarbon liquids in refineries.

Food & Beverage: Sanitary designs for liquid food products like milk and juices.

Burak Metering’s Solutions: Our clamp-on ultrasonic meters allow easy installation without process interruption.

Electromagnetic flow meters use Faraday’s Law to measure conductive liquids by detecting the voltage induced by fluid movement through a magnetic field.

Municipal Water: Widely used in drinking water and wastewater systems.

Mining & Minerals: Handles abrasive slurries in mineral processing.

Pharmaceuticals: Measures conductive liquids in hygienic processes.

Pulp & Paper: Monitors chemical flows in paper production.

Burak Metering’s Advantage: Our mag meters offer high accuracy with minimal maintenance.

Coriolis flow meters directly measure mass flow by detecting the deflection of vibrating tubes caused by fluid movement.

Oil & Gas Custody Transfer: Ensures precise measurement for fiscal transactions.

Chemical Industry: Used for batching and dosing of aggressive chemicals.

Food & Beverage: Measures viscous liquids like syrup and chocolate.

Pharmaceuticals: Critical for high-precision drug formulation.

Burak Metering’s Technology: Our Coriolis meters provide unmatched accuracy in mass flow measurement.

Turbine flow meters measure flow by counting the rotations of a rotor placed in the fluid stream.

Fuel Monitoring: Measures gasoline, diesel, and jet fuel in transport and storage.

Aerospace: Tracks hydraulic fluids in aircraft systems.

Agriculture: Monitors irrigation water flow.

Industrial Lubricants: Measures oil flow in machinery.

Burak Metering’s Turbine Meters: Designed for durability in high-flow liquid applications.

Selecting the best flow meter depends on:

Fluid Characteristics (conductivity, viscosity, cleanliness)

Process Conditions (pressure, temperature, flow rate)

Industry Standards (hygienic, explosion-proof, high-precision needs)

Burak Metering’s Approach: We help industries select the optimal flow meter through expert consultation and customized solutions.

Smart Flow Meters: IoT-enabled devices for remote monitoring and predictive maintenance.

Non-Intrusive Technologies: Increased use of ultrasonic and clamp-on meters.

Sustainability Focus: Flow meters aiding in water and energy conservation.

Burak Metering’s Innovation: We integrate advanced technologies to meet evolving industry demands.

Flow meters are essential for efficiency, safety, and compliance across industries. Whether you need DP meters for oil & gas, ultrasonic for water, mag meters for chemicals, Coriolis for custody transfer, or turbine meters for fuels, Burak Metering offers reliable and high-performance solutions.

Contact Burak Metering today to find the perfect flow meter for your application!

I’m Saeed Lanjekar, founder of Burak Metering. With a background in engineering and technology, I’ve dedicated my career to creating advanced metering solutions that push the boundaries of accuracy and efficiency. At Burak Metering, we’re committed to delivering top-notch technology and driving innovation in the metering industry.

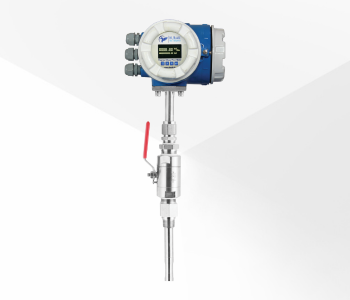

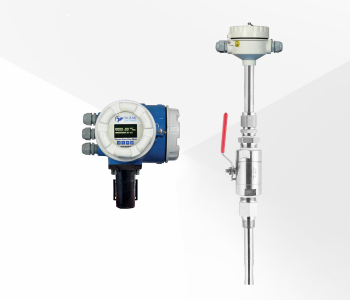

A thermal mass flow meter is a specialized instrument used to measure the flow rate of gases. It operates by heating a sensor in the fluid's path and…

Learn More

A vortex flow meter is a sophisticated device used to measure the flow rate of fluids, including liquids, gases, and steam, within pipelines or condu…

Learn More

An electromagnetic flow meter is an instrument designed for accurately measuring the flow rate of conductive liquids, such as water or various indust…

Learn More

A turbine flow meter is a precision instrument designed to measure the flow of liquids, typically in a pipeline. It operates on the principle of a fr…

Learn More

The oval gear flow meter is a precision instrument used to measure liquids' flow rate in various industrial applications. It operates on positive dis…

Learn More

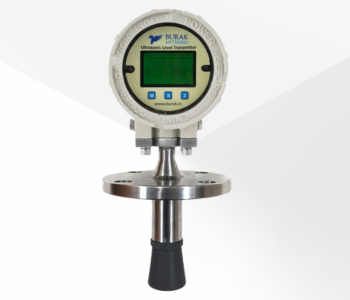

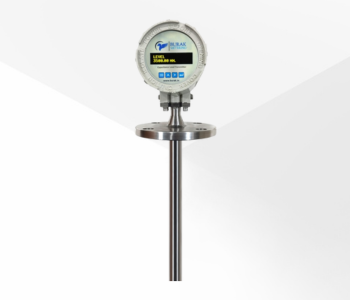

An ultrasonic level transmitter is an innovative device used to gauge the level of liquid or solid substances within a container or tank. With its no…

Learn More

A capacitance level transmitter is a precision instrument that measures levels of liquids, solids, or slurry substances within tanks or containers. I…

Learn More

A hydrostatic level transmitter is an instrument used to measure fluid levels within tanks or containers by utilizing the pressure exerted by the liq…

Learn More

An infrared gas detector is a device used to detect the presence of gases in an area, often as part of a safety system. These detectors can be portab…

Learn More

A Coriolis mass flow meter is a highly accurate instrument used to measure the mass flow rate of fluids, including liquids, gases, and slurries. It w…

Learn More

The Burak BV-5000 Series Cone Meters are designed to measure a variety of fluids, including gases, liquids, and vapors. These meters utilize differen…

Learn More

An orifice flow meter measures fluid flow by creating a pressure drop across a precisely machined orifice plate installed in the flow path. As the fl…

Learn More

The Burak BN-6000 Series Venturi Flow Meters are designed to measure gases, liquids, and vapors using differential pressure to ensure accurate and re…

Learn More

The Rotary Positive Displacement (RPD) Gas Meter is a highly accurate and dependable solution for measuring gas flow across a variety of industrial a…

Learn More

The Turbine Gas Meter is a highly efficient and accurate device designed for gas flow measurement across various industrial applications. It operates…

Learn More

The BU-7010 Series Ultrasonic Gas Flow Meter is a highly accurate solution for measuring gases such as biogas, natural gas, LPG, and propane and othe…

Learn More

The HMTT-100 Head-Mounted Temperature Transmitter measures temperature and converts it into a standardized analog electrical signal, typically a 4-20…

Learn More

A flame detector is a specialized sensor designed to detect the presence of an open flame by analyzing the radiation emitted during combustion. It pl…

Learn More

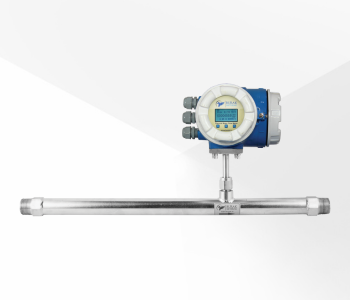

Inline Thermal Mass Flow Meter

Inline Thermal Mass Flow Meter

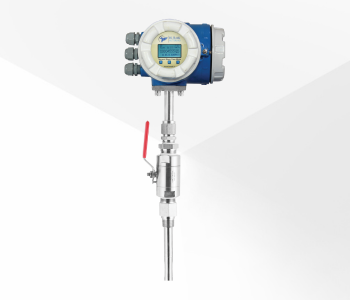

Insertion Thermal Mass Flow Meter

Inline Thermal Mass Flow Meter

Inline Thermal Mass Flow Meter

Vortex flow meter with temperature and pressure compensation

Vortex flow meter with Flange connection

Vortex flow meter with Triclover connection

Electromagnetic Flow Meter with intergral display

Electromagnetic Flow Meter with remote display

Turbine flow meter with flange connection

Turbine flow meter with screwed connection

Turbine Flow Meter with Triclover Connection

Oval Gear Flow Meter with Remote Display

Infrared Gas Detector

Gas Flow Meter with Flange Connection

Gas Flow Meter with Screwed Mount

Insertion Thermal Mass Flow Meter

Inline Thermal Mass Flow Meter

Inline Thermal Mass Flow Meter

Insertion Thermal Mass Flow Meter

Insertion Thermal Mass Flow Meter

Coriolis Mass Flow Meter

Coriolis Mass Flow Meter CNG

Cone flow meter with Differential pressure transmitter

Cone flow meter with Multi Variable transmitter

Slurry Electromagnetic Flow Meter with intergral display

Slurry Electromagnetic Flow Meter with Remote display

RPD Gas Meter

RPD Gas Meter with EVC

Turbine Gas Meter

Turbine Gas Meter with EVC

Ultrasonic Level Transmitter with 4-20mA, 2-wire HART Protocol

Capacitance Level Transmitter with 4-20mA, 3-wire & RS 485 Modbus

Capacitance Level Transmitter with 4-20mA, 2-wire HART Protocol

Hydrostatic Level Transmitter with Inbuilt Display

Hydrostatic Level Transmitter with Remote Display

Ultrasonic Level Transmitter with 4-20mA, 3-wire & RS 485 Modbus

Ultrasonic Level Transmitter with remote display

Turbine Gas Meter with EVC