- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

How to Choose the Right Turbine Gas Meter for Your Application?

TL;DR

- A turbine gas meter must match your gas type, flow range, pressure class, and accuracy needs.

- Quality materials, correct installation, and regular care keep readings steady.

Selecting a turbine gas meter for any process requires a clear evaluation. Each system has different flow ranges, gas types, pressure needs, and accuracy demands.

A precise turbine gas meter helps control gas usage, prevents losses, and supports safe operations.

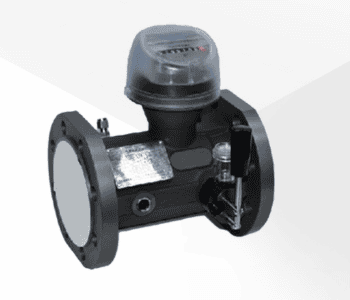

Burak Metering, a leading turbine gas meter manufacturer in India, supplies turbine meters for industries that need steady and reliable performance.

Before picking a device, it helps to understand how these meters function. You can read more about working concepts of turbine gas meter here:

1. Identify Your Gas Type and Application Conditions

Different gases create different flow patterns. Each gas has a specific density and viscosity, and these factors influence rotor speed. You must check whether the meter supports natural gas, LPG, biogas, nitrogen, or air. Gas impurities also matter. Solids, moisture, or oil can affect the rotor. A clean, steady gas stream keeps readings stable.

Pressure range is another deciding factor. Some systems need high-pressure handling, while others run at a low level. Make sure the meter’s load rating fits the line pressure.

Choose accurate turbine gas metering solutions from Burak Metering for reliable industry performance.

2. Check Flow Range and Line Size

A turbine gas meter works best when flow stays inside its rated window. Too slow, and the rotor drags. Too fast, and the rotor may face extra load. Flow range must match the application’s minimum and maximum levels.

Pipe size matters too. A mismatch between meter size and pipeline size affects accuracy. Most industrial systems run through standard diameters, so select a model that fits your existing line.

Before buying, review a dedicated checklist: Things to Check Before Buying a Turbine Gas Meter

3. Look at Accuracy and Repeatability Levels

Accuracy reflects how close the reading is to the actual flow. Repeatability shows how consistent each reading stays during repeated cycles. Both factors help maintain energy balance and billing fairness.

Choose a meter with a clear accuracy class. Higher accuracy helps applications that involve large volumes or billing. For simple monitoring, moderate accuracy can still serve well.

To maintain long-term accuracy, correct installation is vital. You can read about installation issues here: Frequent Turbine Gas Meter Setup Issues and How to Prevent Them

4. Assess Material Quality and Build Strength

A turbine gas meter faces heat, pressure, and continuous movement. The casing, rotor, bearings, and internal supports must stand up to steady use. Stainless steel bodies resist corrosion and wear. Bearings must handle friction and smooth rotation.

Pick a meter that can work through long hours without early wear.

Burak Metering uses tested materials, giving industries confidence in meter durability.

Contact Burak Metering to get strong, high-performance turbine gas meter solutions for industrial applications.

5. Consider Maintenance Needs and Service Support

Every rotating system needs periodic checks. Turbine gas meters work well for long stretches, but dust, moisture, and impurities can still affect them with time. Easy access to internal parts saves time during service.

Follow maintenance tips to increase service life: Maintenance Tips to Extend Turbine Gas Meter Life

Pick a manufacturer that provides service support, spare parts, and quick assistance.

Burak Metering provides support across India, helping users keep equipment in good working condition.

6. Examine Compatibility With Digital Systems

Many industries need digital output. A meter that supports pulse output or smart integration fits well with automation panels. Before selecting, check communication features, output types, and reading options.

Meters that can link with SCADA or monitoring panels help operators track usage and detect irregular flow.

7. Review Certification and Testing Standards

Certification shows that the device has passed quality checks. Look for calibration data, test reports, and compliance with standards. Certifications assure users about meter stability under different gas conditions.

Burak Metering supplies meters built with strict quality processes. Industrial buyers in India trust Burak for consistent output and long service life.

8. Match the Meter to Long-Term Operating Goals

Think about future capacity needs. If your process may expand, choose a meter that handles a slightly wider flow band. This avoids replacement later. Also consider the operating environment. If your area has vibration, heat, or outdoor placement, pick a model suited for those conditions.

Talk to Burak Metering today for turbine gas meter models that support long-term industrial growth.

Contact Burak – India’s Trusted Turbine Gas Meter Manufacturer

Burak Metering stands as one of the top turbine gas meter manufacturers in India due to strong build quality, accurate readings, wide product range, and dependable support.

Industries select Burak because the meters deliver consistent performance under continuous operation.

If you want expert guidance, reliable equipment, and long-term service, Burak Metering is a reliable partner for your gas measurement needs.

Contact us today to learn more or to find the right meter for your application.