- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Things to Check Before Buying a Turbine Gas Meter

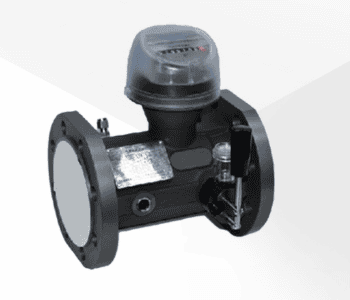

A turbine gas meter plays a crucial role in measuring industrial gas flow. Many users focus on brand names or price, yet the meter’s long-term output depends on several technical and operational checks.

This guide explains the factors that help you pick the right model for steady performance and safe field use.

Burak Metering, one of India’s leading manufacturers of turbine gas meters, offers strong build quality and consistent readings. Explore Burak’s turbine gas meter range to support your plant’s performance.

1. Confirm Flow Range Compatibility

Each turbine gas meter works effectively within a stated flow window. You must match this window with your line’s minimum and maximum demand. If the meter sits outside this zone, the rotor speed may vary, which can distort readings.

Check:

- Minimum measurable flow

- Peak flow the meter can handle

- Expected flow changes during plant shifts

If your team wants a quick explanation of how turbine gas meters respond to speed variation, review this guide: Turbine Gas Meters: Working, Benefits, Industrial Uses.

2. Assess Pressure and Temperature Ratings

Gas conditions change frequently in industrial lines. Your chosen turbine gas meter must withstand these shifts. A mismatch can slow rotor activity or stress the internal build.

Review:

- Maximum pressure

- Operating temperature band

- Material strength for your gas type

Turbine Gas Meters built by Burak Metering follow strict quality checks to support steady operation under harsh field conditions. Reach out to learn how Burak meters handle pressure shifts in process lines.

3. Study the Working Principle

A clear grasp of the meter’s internal action helps you judge if the design suits your application. A turbine model measures flow by converting gas velocity into rotor motion. Sensors track rotor speed and convert it into volume.

To read a simple breakdown, you can visit: Turbine Gas Meter Working Principle.

Select a model that keeps stable rotor movement with minimal friction. This supports long service life and smooth reporting.

4. Verify Accuracy Class and Repeatability

Accuracy affects operational cost, fuel planning, compliance steps, and billing. Many plants ignore this factor and later face drift in readings.

Key points:

- Accuracy class stated by the manufacturer

- Repeatability during steady flow

- Performance during low-flow periods

A turbine gas meter from Burak Metering maintains steady output due to tight internal clearances and balanced rotor design. Talk to Burak’s team today for guidance on accuracy performance.

5. Inspect Build Material and Mechanical Strength

Gas lines may carry dry gas, wet gas, or gas with dust traces. Your meter must handle these conditions. Poor material choice may cause early wear, rotor imbalance, or bearing stress.

Check for:

- Corrosion-resistant housing

- High-strength rotor material

- Bearings with low friction

- Protection for electronics

6. Evaluate Installation Needs

Incorrect installation causes major flow errors. Before buying a turbine gas meter, check if it requires straight pipe lengths, specific mounting positions, or vibration control. These details affect the final measurement.

Review:

- Required upstream and downstream lengths

- Pipeline alignment

- Effects of valves and bends

- Vibration from compressors

You can read a full guide on common installation mistakes here: Avoid These Common Turbine Gas Meter Installation Mistakes.

7. Check the Maintenance Load

A turbine gas meter offers long service, but it still needs cleaning, lubrication of bearings, and routine checks. Before purchasing, confirm if the model you plan to use supports easy access for field technicians.

Look at:

- Ease of rotor inspection

- Access to internals

- Frequency of service steps

For efficient upkeep, review this quick guide: Maintenance Tips to Extend Turbine Gas Meter Life.

Burak Metering develops meters that simplify field maintenance. Ask the Burak team for models offering quick service access.

8. Review Communication and Output Options

A modern plant depends on clear data reporting. Confirm if your chosen meter supports your SCADA, PLC, or digital control system.

Check:

- Pulse output

- Temperature and pressure correction options

- Compatibility with your data platform

Selecting the right output module helps you avoid future integration expenses.

9. Consider Calibration and Testing Support

Calibration confirms that the meter continues to match its original accuracy class. Before buying, confirm if the manufacturer offers calibration support and provides test certificates.

Burak Metering offers reliable calibration services for gas meters used across industries. This helps your plant maintain safe and consistent performance.

10. Investigate After-Sales Support

Good support protects your investment. A manufacturer that offers fast guidance, spare parts, and technical assistance keeps your equipment running smoothly.

Burak Metering maintains strong support channels across India, making it a dependable choice for long-term industrial use.

Contact Us

Burak Metering stands as a top gas meter manufacturer in India.

We deliver accurate, stable, and durable gas metering products for industrial applications. Its engineering strength, service quality, and field support help users maintain consistent results.

If your facility demands reliable turbine gas meters backed by experienced experts, Burak Metering is the right choice for dependable performance and responsive service across the country.

For product details, service support, or project inquiries, connect with Burak Metering and receive prompt assistance backed by proven field experience.