- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

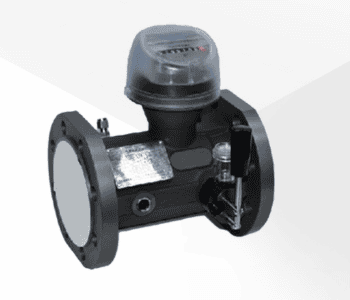

Frequent Turbine Gas Meter Setup Issues and How to Prevent Them?

Turbine gas meters support accurate flow tracking across industrial operations.

A correct installation helps the device run consistently and prevents long-term faults. Many issues arise because small steps are missed during setup.

This guide highlights the most common mistakes and shows how to prevent them.

For additional technical references, you may also check Turbine Gas Meters Working and Uses, and Mechanical vs Electronic Turbine Gas Meters.

1. Incorrect Pipe Alignment

Proper pipe alignment supports a smooth entry path for gas movement. Misaligned pipes create swirl and vibration, which disturb the rotor. This shift leads to unstable readings. A straight pipe section before and after the meter gives the rotor a reliable flow pattern.

Many sites overlook this because system upgrades may force quick installations, but the long-term accuracy loss makes this mistake costly.

2. Improper Flow Conditioning

Turbine meters react strongly to flow quality. If flow arrives uneven or disturbed, the rotor speed changes irregularly. A flow straightener or conditioning element stabilizes the stream before it reaches the meter. Without this, even a new installation may produce inconsistent values under normal pressure ranges.

Adding a simple straightener device protects the unit and improves performance.

3. Wrong Meter Orientation

A level position helps the rotor move freely. If the meter sits at an angle, internal parts face extra friction. This increases wear and affects measurement output.

Some installations place meters on uneven surfaces, which shifts the unit’s axis. A firm and level mount prevents this. Orientation checks take little time but protect long-term accuracy.

4. Incorrect Meter Size

Choosing the wrong meter size leads to major flow errors. A large meter misses low flow activity. A small meter overloads quickly. Many decisions get made based on convenience rather than flow demands.

The best choice comes from analyzing pressure, flow rate, and gas type. A correct fit allows the meter to run within its rated range and reduces strain.

5. Ignoring Gas Cleanliness

Gas quality has a direct effect on rotor lifespan. Dirt, rust, or liquid traces damage turbine blades. They reduce rotation speed and create long-term drift.

Some teams assume the line stays clean after an initial flush, but deposits build with time. A filter or strainer protects the rotor and maintains stable movement. Contamination problems are common but preventable.

6. Missing or Weak Support Brackets

Pipelines move due to pressure changes, vibration, or external activity. If the turbine gas meter lacks strong support, this movement transfers stress to the device. Bearings and internal parts then face extra load. Proper brackets secure the meter and prevent shaking. A firm mount keeps the rotor path stable and reduces reading fluctuations.

7. Wrong Gasket Type

Some gaskets extend into the gas path and disturb flow. Others fail under high pressure. A flat, firm gasket that stays clear of the bore maintains proper sealing without blocking movement.

During installation, the gasket must sit evenly. A slight intrusion affects rotor speed and creates measurement issues.

8. Imbalanced Bolt Tightening

Bolts must remain tight enough to prevent leaks yet loose enough to avoid deforming the meter body. Extra force bends the housing.

Low force causes leaks that influence flow stability. Following the recommended torque range gives the best result. A balanced approach keeps the meter aligned and free of structural stress.

9. Poor Electrical Connections

Electronic turbine meters require safe wiring. Loose connections or broken cables cause signal drops. This leads to inconsistent pulses or noisy output. Connecting and routing wires with care protects the signal from interference. Shielded cables improve stability and help maintain clean readings.

10. Neglecting Calibration

Calibration confirms that the meter still matches real flow conditions. Wear and friction slowly shift the meter’s sensitivity.

Many facilities delay calibration because of busy schedules, leading to long-term measurement drift. A planned calibration cycle keeps records trustworthy and prevents unexpected errors.

11. Weak or Irregular Maintenance

Maintenance provides early alerts on wear or damage. Tasks like cleaning the rotor, checking bearings, and inspecting seals keep the meter in stable condition.

Many plants postpone maintenance due to workload pressure. A small routine check prevents expensive breakdowns and protects device lifespan.

Contact Us

Burak Metering stands as a top turbine gas meter manufacturer in India.

We focuses on precise engineering, steady performance, and strong service support. Industries rely on Burak for accurate turbine gas meters suitable for demanding conditions.

Reach out to us to get high-quality flow measurement systems backed by deep field experience and consistent customer guidance.