- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Maintenance Tips to Extend Turbine Gas Meter Life

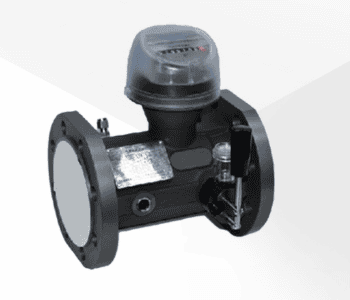

Turbine gas meters remain a reliable choice for stable gas measurement in industrial and commercial systems in India.

Their long service span depends on simple care steps that protect moving parts and keep readings steady.

This technical guide highlights practical actions that support turbine gas meter durability and smooth performance across various operating conditions.

If you want a deeper look at how turbine gas meters work, you can read this technical guide: Turbine Gas Meters: Working to Application

1. Keep the Gas Stream Clean

Gas purity plays a major role in extending meter life. Dust, liquid traces, and small particles can strike the rotor blades and reduce efficiency over time. A clean gas stream lowers the risk of internal scratches and helps the rotor maintain steady motion.

Use filtration that matches your line conditions and review filter status at fixed intervals. Clean filter elements support stable flow and reduce load on bearings.

→→ Frequent Turbine Gas Meter Setup Issues and How to Prevent Them

2. Monitor Rotor and Bearing Condition

The rotor and bearing assembly handles constant motion, making it essential to check for wear. Early detection prevents damage from spreading. Look for reduced rotation speed, vibration signs, or slight imbalance.

A planned inspection cycle avoids disruptions and supports long-term accuracy.

To compare meter types before planning maintenance, you may find this technical guide useful: Mechanical or Electronic Turbine Gas Meter? Best Choice for Indian Plants

Reach out to Burak Metering if you need guidance on maintaining turbine gas meters in your plant.

3. Check Alignment After Line Changes

Pipe stress, heavy vibration, or nearby equipment adjustments may shift the meter from its intended position. Even a small misalignment can place uneven pressure on the rotor and restrict blade movement.

Review bolt tension, flange fit, and gasket condition whenever you adjust nearby components or restart the line after a shutdown. Correct alignment supports consistent flow measurement and lowers long-term wear.

4. Stabilize Flow, Pressure, and Temperature

Steady operating conditions keep mechanical parts safe from overload. Large shifts in pressure or temperature may strain bearings or disturb rotor balance. Install a straight-run pipe section upstream to smooth turbulence and keep flow uniform.

This simple step improves meter lifespan and supports predictable readings.

Upgrade to Burak’s turbine gas meters engineered for consistent measurement under variable load conditions.

5. Track Vibration and Noise Patterns

Unusual sound or vibration often signals changes inside the meter. Slight humming may point to flow irregularities, while stronger pulses may indicate bearing wear or alignment issues.

Record baseline readings and compare them over time. Early action prevents damage that could shorten meter service life.

Burak’s support team can help you identify vibration causes and suggest corrective steps.

6. Follow Routine Calibration Schedules

Calibration keeps readings accurate as parts age. A predictable calibration cycle reduces errors and verifies the performance of the rotor, blades, and related components.

Sites with high-volume flow may need more frequent checks. Keep calibration logs for audits and performance reviews.

7. Lubricate Mechanical Components Correctly

Proper lubrication helps reduce friction and protect moving parts. Avoid excess lubrication, which can trap debris inside the meter. Always use the grade recommended for your meter type and clean the lubrication points before refilling.

This simple step keeps the rotor and bearings in healthy condition.

Contact us for guidance on lubrication schedules for turbine gas meter models.

8. Protect Electronic Parts in Hybrid Models

Some turbines gas meters use electronic sensors or digital modules. These components need dry, clean environments to function well. Check cable joints, seals, and enclosures for cracks or moisture.

A stable power supply also supports long sensor life.

9. Train Operators on Proper Meter Handling

Operators must handle meters with care during inspections, installation, and cleaning. Use the right lifting tools, avoid sudden impact, and follow correct opening steps. Small mistakes during handling may affect sensitive components.

A well-trained team helps protect meter life and reduces unwanted maintenance work.

10. Replace Consumable Parts Before Failure

Filters, O-rings, and gaskets reach natural wear points over time. Replacing them early preserves sealing strength and keeps readings accurate. Plan this replacement cycle based on flow rates and operating hours.

Conclusion

Long turbine gas meter life depends on simple habits: clean gas flow, routine inspection, steady alignment, and structured calibration. Small steps taken consistently protect the rotor, bearings, and housing from premature wear. These actions help facilities maintain accurate readings, reduce downtime, and cut costs linked to unplanned repairs.

Burak Metering stands among India’s leading turbine gas meter manufacturers due to strong engineering, material quality, and dependable support. Industries across the country trust Burak turbine gas meter for stable performance in varied conditions.

Burak teams guide customers in model selection, installation, and maintenance, helping plants operate with confidence and accuracy.

For product details, service support, or project inquiries, connect with Burak Metering and receive prompt assistance backed by proven field experience.