- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Working Principle of Turbine Gas Meters

TL;DR

- The working principle of a turbine gas meter is based on a rotor that spins as gas flows through the meter.

- The rotor’s spin rate generates electrical pulses.

- These pulses correspond directly to the volumetric flow rate of the gas.

- Measurement accuracy depends on:

- Clean and stable gas flow.

- Correct installation of the meter.

- Proper compensation for pressure, temperature, and gas condition variations.

Turbine gas meters measure volumetric flow by converting the movement of gas into rotational motion and then into an electrical signal. This method emphasizes a direct relationship between fluid velocity and rotor speed.

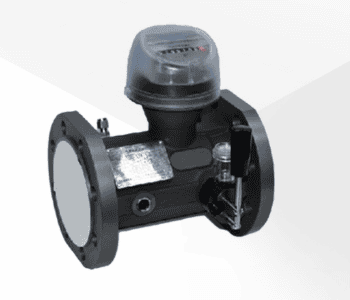

Basic Setup and Components of Turbine Gas Meter

A turbine gas meter places a multi-bladed rotor inside a straight section of pipe. The rotor sits in the flow path so that the moving gas strikes the blades and causes the rotor to spin.

Upstream flow straighteners or vanes are often provided to reduce swirl and ensure the rotor sees a stable flow profile.

A magnetic or optical sensor detects each blade (or magnet mounted on blades) passing by a pick-up point and generates a pulse for each event.

Learn More: Turbine Gas Meters: Working to Application

Conversion from Rotor Speed to Flow Rate

As gas flows faster, it imparts more force on the blades; the rotor spins more rapidly. The rotational speed is approximately proportional to the volumetric flow rate (for given gas conditions).

The pick-up sensor produces pulses whose frequency (pulses per second) is proportional to rotor speed. A factory-calibrated constant (K-factor) converts pulses into volume units.

Hence:

Flow rate = K × (pulse frequency)

Gas-Specific Considerations

When the measured medium is a gas rather than a clean liquid, some additional factors apply:

- Gas density and temperature can influence the flow behavior and rotor response; for accurate volumetric measurement, one may need compensation for pressure and temperature.

- The flow profile must be steady and free of large particulate or two-phase flow, because the rotor can be disturbed, reducing accuracy.

- The rotor and bearings must be appropriate for low viscosity, high-velocity gas applications; installation must ensure clear upstream and downstream straight pipe runs to stabilize flow.

Key Advantages and Limitations of Turbine Gas Meter

Advantages

- High linearity between rotor speed and flow rate across a well-defined range of gas velocities.

- Rapid response to changes in flow, because the rotor spins almost immediately when gas passes.

- The output signal is simple (frequency pulses) and integrates easily with electronic monitoring and control systems.

Limitations

- At very low flow rates, the rotor may not spin freely, reducing accuracy.

- Dirty gas with entrained particles or condensate can damage the rotor or bearings and degrade measurement over time.

- Flow disturbances (swirl, eccentric flow, pulsations) upstream or downstream can disrupt the rotor behavior unless proper straightening is provided.

- The meter’s accuracy may depend on constant gas conditions (density, temperature), so for custody-transfer or high-precision applications, compensation may be required.

Practical Installation and Calibration Notes

- The meter should be installed with sufficient straight pipe length upstream (often tens of pipe diameters) to reduce flow irregularities.

- A calibration certificate specifying the K-factor (pulses per unit volume) should come from the manufacturer.

- To maintain accuracy over time, periodic checks or recalibration may be needed, especially if gas composition, pressure or temperature vary.

- Filters or strainers may be fitted upstream to protect the rotor from debris.

- For gas flow measurement, if volume must be converted to mass (for some applications) further instrumentation may be needed to account for density and temperature.

Summary

The principle of a turbine gas meter is simple: gas flow drives a rotor; the rotor’s speed produces pulses; those pulses link directly to volumetric flow. Proper installation, clean flow, correct calibration, and attention to gas conditions permit accurate, reliable measurement.

Understanding this principle supports better selection, installation, and maintenance of turbine gas flow meters.

If you need a reliable Turbine Gas Meter in India, trust Burak, a top gas flowmeter manufacturer in India.

Our flowmeters are engineered to precise standards, manufactured with quality materials, and calibrated to industry benchmarks.

We support you from selection through installation and ensure performance in your gas measurement applications.

Choose Burak Metering for a partner committed to dependable flow measurement and service excellence.

For inquiries, quotations, or technical support, reach out to us directly, and our team will assist you promptly.

Contact Details:

Phone: tel:+91 8655587403

Email: info@burak.in

Address: 404/B, Virani Business Centre, Opp Bharat Gear Company, Kausa, Mumbra, Thane 400612