- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

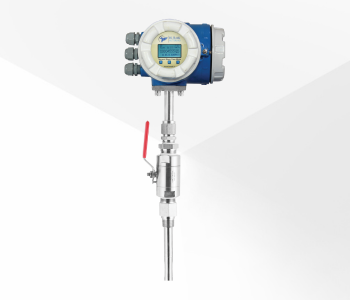

What Is an Insertion Type Electromagnetic Flow Meter + Uses & Benefits

An insertion-type electromagnetic flow meter is a flow sensor that is inserted into a pipe through a small tap or hole. It has a probe or sensor rod that extends into the flow stream. The sensor section generates a magnetic field across the fluid. As the conductive fluid moves, it induces a voltage that the electrodes sense. The voltage is proportional to flow velocity by Faraday’s law. (see more on the working principle of the electromagnetic flowmeter)

Unlike full-bore electromagnetic flow meters that require replacing a section of pipe, insertion types require only a small opening. This makes them easier to add to existing pipelines. They are suited for large pipes or retrofit installations. Many insertion meters can operate with minimal interruption and at a lower cost.

The major parts include:

- A sensor rod or probe inserted into the line

- Electrodes to pick up the induced voltage

- Magnetic coils or excitation coils

- A transmitter/converter unit to process signals

The sensor rod is placed at a depth specified by the manufacturer, allowing it to sample near the center of the flow. The transmitter filters, amplifies, and converts the induced voltage to a flow reading (volume per time).

Because insertion meters disturb flow less and require less structural change to pipework, they are often chosen when cost and downtime matter.

Learn more about what electromagnetic flow meters are.

Advantages and Limitations of Insertion-Type Electromagnetic Flow Meters

Here are key benefits:

- Lower installation cost

Insertion meters need only a small insertion point, not full pipe replacement. This lowers expense and disruption. - Minimal downtime/disruption

The meter can often be installed without draining the pipe fully. Hot-tap installation is possible in many cases. - Scalable for large pipe diameters

They work well with large pipelines where full-bore meters would be very expensive. - No moving parts

Because there are no mechanical moving parts, wear and tear is lower, and maintenance demands are less. - Insensitive to fluid properties

The measurement does not depend on fluid density, viscosity, pressure, or temperature (provided conductivity is adequate). - Ability to measure dirty or corrosive fluids

They tolerate fluids with solids, slurries, or corrosive chemicals, as long as electrical conductivity is sufficient. - Bidirectional measurement

The meter can detect flow in either direction (forward or reverse) because the induced voltage reverses. - Low pressure drop

Because the flow path is mostly unobstructed, pressure loss across the meter is minimal.

However, there are limitations:

- The fluid must be electrically conductive above a minimum threshold (often a few µS/cm). It fails on nonconductive media like pure hydrocarbons or gases. The fluid must meet a minimum conductivity requirement.

- Very low flow speeds can reduce signal strength and accuracy.

- The insertion depth, alignment, and turbulence near the sensor influence accuracy.

- Liners or electrode surfaces may degrade over time under aggressive media.

- Installation errors (e.g., misalignment, air bubbles, partial filling) can produce errors.

You can also read about the advantages and disadvantages of electromagnetic flow meters.

Applications and Use Cases of Insertion-Type Electromagnetic Flow Meters

Insertion-type electromagnetic flow meters find use in many industries and fluid systems. Below are common applications and typical use cases:

Water and Wastewater Treatment

They monitor flow in municipal water supply lines, sewage systems, and effluent streams. They help detect leaks, balance network flow, and meter process water.

Industrial Process Control

In chemical plants, they measure flows of acids, alkalis, or other conductive chemicals. They help in dosing, mixing, and balancing process streams.

Mining and Slurry Flows

They handle slurry lines, tailings return, and mining process waters with suspended solids. Their tolerance to abrasive content makes them suitable for these harsh settings.

Power Plants and Cooling Water

They measure cooling water flows, feedwater, or condensate return flows. Accurate flow data helps in thermal efficiency and system control.

Food, Beverage, and Pharmaceutical

When fluids are conductive (e.g., saline or with additives), they can measure process or cleaning flows. Their design can use sanitary materials.

Retrofitting Existing Pipelines

Insertion meters allow adding flow measurement capability to existing infrastructure without cutting out pipe segments. This is especially helpful in water networks or legacy systems.

Network Flow Surveys

In large distribution networks, insertion meters can be moved between sites to profile flows without permanent installation.

Practical Use and Guidance of Insertion-Type Electromagnetic Flow Meters

To get accurate readings and long service life, one must follow these guidelines:

- Insert at correct depth: The sensor must reach into the flow core (not too shallow).

- Align properly: The sensor face or electrode axis must face perpendicular to magnetic field lines.

- Avoid turbulence and disturbances: Place the insertion point away from bends, valves, or fittings to reduce error.

- Grounding and electrical isolation: The meter electrodes need a stable reference; use ground rings or proper grounding if the pipe is coated or insulated.

- Ensure full pipe fill: The pipe should be filled with liquid; partial flow or air pockets degrade accuracy.

- Calibration and maintenance: Periodic calibration and electrode cleaning help maintain accuracy.

- Choose compatible materials: Select liners, electrode metals, and body materials that resist corrosion and wear for the fluid handled.

- Monitor conductivity: If fluid conductivity changes, the meter signal might weaken.

In many systems, two to three pipe diameters upstream and downstream of the straight run are sufficient to stabilize the flow before measurement.

Burak Metering stands out as a top electromagnetic flow meter manufacturer in India. We build mag flow meters with high precision, low maintenance, and a wide choice of liner and electrode materials. Our devices support features like bi-directional measurement, empty-pipe detection, and remote interfaces (4-20 mA, RS485, Modbus). Because we operate locally, we can deliver faster lead times, supply spare parts quickly, and provide on-site support.

You should choose Burak because we combine strong technical features with local presence. Our in-house calibration lab meets ISO/IEC 17025 standards, giving traceable accuracy. Our flowmeter product line covers a broad size range and many industrial fluids, so you can pick a model suited to your process.

To discuss your flow measurement requirements or request a quotation, contact Burak Metering today.