- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

What Are Electromagnetic Flow Meters? Principles, Benefits & Applications

Why does precise flow measurement matter so much in modern industry? Accurately measuring flow contributes significantly to efficiency, product quality, and operational sustainability across various sectors.

Understanding exactly how much liquid moves through a system allows businesses to optimize processes and conserve resources.

Electromagnetic flow meters, often called magmeters, represent a vital technology for measuring conductive liquids.

These devices provide accurate measurements without direct contact with the flowing medium.

This guide explores what Electromagnetic flow meters are, their operational principles, key benefits, important applications, and practical considerations for selection, installation, calibration methods, and frequency.

Understanding Science of Electromagnetic Flow Meters

1. What is an Electromagnetic Flow Meter?

An electromagnetic flow meter, or magmeter, measures the flow of conductive liquids using electromagnetic principles. It creates a magnetic field, then gauges the fluid's passage. These devices are volumetric flow meters.

2. How Electromagnetic Work: Faraday's Law in Action

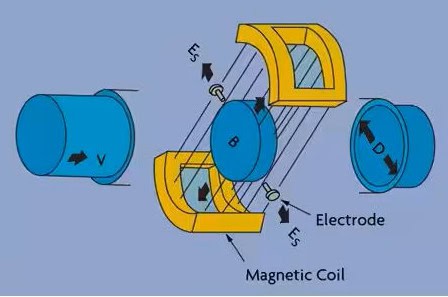

Magnetic flow meters operate based on Faraday’s Law of Electromagnetic Induction. This fundamental law states that when a conductive fluid moves through a magnetic field, it generates an electrical voltage. This induced voltage directly correlates with the fluid's velocity.

Key components facilitate this process:

- Magnetic Coils: These coils create the necessary magnetic field.

- Electrodes: Positioned within the flow tube, these detect the induced voltage.

- Flow Tube: This section channels the fluid, thus confirming consistent passage through the magnetic field for precise measurement.

- Transmitter: This unit processes the voltage signals received from the electrodes, converting them into a quantifiable flow measurement.

The induced voltage remains unaffected by the liquid's physical properties such as temperature, viscosity, pressure, density, and conductivity, provided the conductivity exceeds a minimum level. For reliable readings, the pipe must remain full of liquid.

3. What Magmeters Measure (and What They Can't)

Magmeters are suitable for measuring a broad spectrum of conductive fluids. Common examples include:

- Water: This includes potable water and wastewater systems.

- Wastewater: Magmeters monitor sewage and industrial wastewater flows.

- Chemicals: They handle aggressive or corrosive chemicals.

- Slurries: These instruments work well with abrasive slurries.

- Food-grade liquids: These can be milk or juices.

However, these devices cannot measure non-conductive fluids like oils, steam, or gas. Other flow meter technologies, such as differential pressure types, handle such materials.

Why Electro Magmeters Are the Preferred Choice in Industries

1. No Moving Parts: A Basis of Reliability

A significant benefit of electromagnetic flow meters comes from their absence of moving components. Traditional mechanical flow meters frequently encounter wear and tear, especially with abrasive or corrosive fluids.

Magmeters avoid this mechanical wear, leading to greater durability and consistent performance. This design also results in reduced maintenance requirements and lower operating costs. Their non-intrusive nature means they do not obstruct the fluid path, preserving flow.

2. Exceptional Accuracy and Precision

Electromagnetic flow meters provide outstanding accuracy when measuring conductive fluids.

They offer highly reliable readings, even in challenging environments. This precision makes them an indispensable tool for sectors demanding exact flow measurements, such as water treatment and chemical processing.

Accuracy over a broad flow range can be ± 0.5% of the flow rate or better. This level of accuracy directly translates to cost reduction and improved efficiency.

3. Versatility and Bi-directional Flow Measurement

These meters show remarkable versatility, capable of measuring a broad array of conductive liquids, from clean water to complex slurries and aggressive chemicals. They also operate effectively in harsh conditions, including high-pressure systems and corrosive environments.

A notable capability is bi-directional flow measurement. While many flow meters measure in only one direction, magmeters can measure flow regardless of its course. This simplifies industrial systems that include bi-directional flows.

4. Cost-Effectiveness and Energy Efficiency

Electromagnetic flow meters often represent a higher initial expenditure compared to mechanical alternatives, but their long-term benefits frequently outweigh this upfront cost.

They require minimal upkeep, substantially cutting ongoing maintenance expenses. Their high accuracy also minimizes operational inefficiencies like leaks or incorrect readings.

Furthermore, magmeters operate with minimal power. This energy-efficient design reduces overall energy consumption and promotes sustainable operations.

5. Ease of Integration and Modern Connectivity

Modern electromagnetic flow meters integrate smoothly with existing control systems.

They can connect with digital monitoring platforms, including remote data logging, allowing businesses to track flow data in real time. This connectivity improves operational control and supports informed decision-making.

These meters fit well with Industry 4.0 and increased automation.

Learn more about the advantages and disadvantages of the electromagnetic flow meter.

Looking for the right magmeter for your industry? Get expert guidance from our flow specialists today.

Electromagnetic Flow Meter's Applications Across Industries

Magmeters serve critical functions in many industrial sectors.

- Water and Wastewater Treatment: They prove integral to management systems, monitoring consumption, detecting leaks, and assisting with accurate billing. In sewage systems, they provide data for controlling flow rates and preventing overflows.

- Chemical and Pharmaceutical Industries: These meters handle aggressive chemicals and corrosive liquids accurately. They measure high-purity liquids in pharmaceutical production, maintaining safety and regulatory compliance.

- Food and Beverage Industry: Magmeters play a vital part in maintaining hygiene standards for food-grade liquids like milk and juices. Their non-intrusive design helps prevent contamination.

- Mining and Slurry Applications: Their durability and lack of moving components make them well-suited for abrasive materials and slurries.

- Power Generation: Power plants use magmeters to monitor cooling water flow and other essential process fluids. This helps optimize plant efficiency and operational safety.

- Agriculture and Irrigation: Accurate water flow measurement is vital in agriculture. Magmeters present a low-maintenance option that meets industry standards.

- Oil & Gas: They find application in water transfer, produced water measurement, and brine injection.

- Industrial Applications: These tools are valued for their durability and ability to withstand high pressure in various industrial settings. They can qualify for Class 1, Division 2 classifications for hazardous areas.

Electromagnetic Flow Meter's Advanced Features & Specialized Technologies

1. Magmeter Types for Specific Needs

Several magmeter designs meet varied application requirements.

- Full-Bore (In-line) vs. Insertion Type: Full-bore meters generally suit smaller line sizes. In contrast, full-profile insertion electromagnetic flowmeters can be a cost-effective alternative for larger projects.

- Specialized Designs: Options include hygienic (sanitary) versions for the food/pharma sectors, wafer styles, and flanged models.

2. Enhanced Signal Processing and Noise Reduction

Manufacturers continually innovate to improve performance, especially in challenging environments.

- Pulsed DC Technique: This technique effectively eliminates interfering noise and provides automatic zero correction.

- Functional Magnetic Field Distribution (F.F): Toshiba's technology provides accurate flow measurement even with uneven flow profiles.

- Noise-Suppressor Against Slurry Noise: Toshiba's original circuit actively suppresses slurry noise, achieving stable and precise flow measurement.

- Divided Multi-Sampling System: This system uses advanced algorithms, ensuring stable flow measurement with high accuracy.

3. The Smart Transmitter: More Than Just a Converter

The transmitter unit performs more than simple voltage conversion. It offers various functionalities:

- Output Signals: Transmitters can provide analog, pulse, or digital communication protocol outputs.

- Diagnostic Capabilities: These features assist with real-time monitoring and process control.

- Local Display & Data Logging: They allow on-site data visibility and recording.

Practical Guide to Choosing, Installing, and Maintaining Your Electromagnetic Flow Meter

1. How to Choose the Right Mag Flow Meter

Selecting an electromagnetic flow meter requires careful consideration of several factors.

- Fluid Characteristics: Match the meter’s specifications to the fluid’s temperature, conductivity, flow range, and pressure.

- Required Accuracy: Determine the precision needed for your business operations, as some meters offer greater exactness (e.g., full-bore vs. full-profile insertion). Accuracy becomes a return on investment over time.

- Cost and Value: Though initial costs may exceed those of mechanical meters, consider the long-term savings from reduced maintenance and improved accuracy.

- Pipe Size and Installation Type: Your project’s line size and location will determine whether a full-bore or insertion meter is best suited.

- Compliance with Industry Standards: Always select meters that adhere to standards such as ISO or IEC certifications for performance and reliability. For drinking water, look for NSF-61 certifications; for hazardous areas, seek Class 1, Division 2 classifications.

2. Essential Installation Best Practices

Proper installation contributes significantly to meter accuracy and longevity.

- Optimal Location: Choose an area with full flow and minimal interference. This avoids turbulence or obstructions.

- Straight Pipe Requirements: While in-line meters generally need less straight pipe, insertion mag meters require a minimum of 10 pipe diameters downstream and 5 pipe diameters upstream for proper function.

- Crucial Grounding: Following grounding instructions is essential to prevent static electricity from the fluid interfering with readings.

- Preventing Air Bubbles: Air bubbles in the pipe can affect accuracy. Make sure liquid fills the pipe. Installing the sensor at recommended angles helps eliminate bubble risk.

3. Overcoming Challenges & Maintenance Tips

While magmeters boast low maintenance, some considerations exist.

- Liner Separation: Some EM flow meters use a separate liner that can detach, potentially needing repairs.

- Fluid Conductivity Limits: Operating a meter near its electrical conductivity limit can cause it to shut off. Always provide an allowance for changes in fluid composition or operating conditions.

- Slurry Management: For slurries, size magnetic flow meters to operate above 1 ft/sec to prevent solids from settling. For abrasive slurries, sizing for lower velocity (below 3 ft/sec) can reduce wear.

- Gravity-Fed Pipes: These pipes might require a larger magmeter to reduce pressure drop, ensuring the necessary liquid volume passes without backing up.

- Calibration and Verification: Regular calibration and verification are important to maintain accuracy over time. Check out Common Errors and Troubleshooting of Electromagnetic Flowmeters

for a detailed fault-and-fix guide.

Electromagnetic Flow Meters Future Trends and Innovations

Magmeters continually adapt to industrial advancements.

- Integration with Industry 4.0 and IoT: They are perfectly suited to integrate with digital monitoring systems, supporting increased automation.

- Predictive Maintenance and Advanced Analytics: Data collected from magmeters can power predictive maintenance strategies and advanced analytics.

- Material Science Progress: Expect continued development in sensor and liner materials for even harsher environments.

Conclusion

Electromagnetic flow meters, or magmeters, have become indispensable for precise, reliable, and low-maintenance flow measurement of conductive liquids.

Their applications span from water treatment to chemical processing, and they provide critical data for operational efficiency and sustainability.

Magmeters’ benefits in accuracy, durability, and integration actively support data-driven decision-making in industries today.

Businesses wishing to boost process efficiency and decrease maintenance expenses should seriously consider these devices.

Their energy-efficient design, lasting reliability, and straightforward integration make them an excellent choice for modern industrial applications.

By adopting this technology, companies can improve operational performance and contribute to a more sustainable future.

Ready to optimize your process? Contact us today for India's best electromagnetic flow meter manufacturer technology and support.