- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

How to Verify Turbine Gas Meter Accuracy Before Buying?

Verifying turbine gas meter accuracy before purchase helps prevent measurement errors that impact process safety and operational costs.

Buyers who want stable performance can follow a clear set of checks.

This technical guide explains practical steps that help you confirm meter precision and reliability during evaluation.

Burak Metering, a leading turbine gas meter manufacturer in India, follows strict production and testing methods, which makes these steps easy for buyers to apply.

1. Check the Meter’s Calibration Certificate

A valid calibration certificate shows the meter test process, the equipment used, and the final results. Review the certificate date, test conditions, and allowable error limits.

A current certificate confirms the meter passed all accuracy checks under controlled settings. This document allows you to compare the manufacturer’s claimed accuracy with verified results.

For more details on how a turbine meter works during testing, check the turbine gas meter working principle.

Contact Burak to request certified calibration documents for your next turbine gas meter.

2. Confirm Flow Range and Repeatability

Accuracy depends on proper flow range selection. Check the minimum and maximum flow rates the meter can handle. If the meter operates outside this range, readings may shift.

Repeatability data shows how stable the readings stay across multiple test cycles. A meter with consistent repeatability delivers reliable performance in long-term use.

You can study related factors in things to check before buying a turbine gas meter, which offers supporting guidance for buyers.

3. Review Linearity Test Results

Linearity represents how well the turbine gas meter reads across different flow points. Test data should show smooth variation without large jumps. A consistent linearity curve indicates balanced rotor response and accurate electronic pickup.

A quality manufacturer tests several points within the declared range and shares this information without hesitation. Burak Metering follows this practice for all turbine gas meters.

Ask the Burak technical team for detailed linearity charts before finalizing your order.

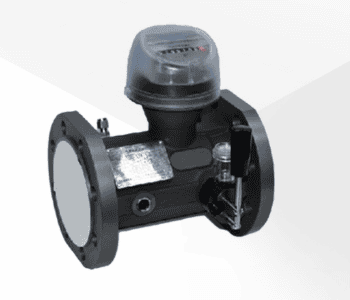

4. Inspect Build Quality and Rotor Balance

A turbine meter depends on smooth rotor movement. Look for strong construction, clean welding, well-machined internals, and a steady rotor. Any friction or imbalance reduces measurement accuracy. The rotor should spin freely with minimal resistance. You can also check for bearing quality, blade finish, and internal clearances.

If you want deeper insights into how turbine flow meters work in real applications, read Burak’s guide on turbine gas meters, working, benefits, and industrial uses.

5. Evaluate Signal Output Stability

Signal stability affects reading consistency. Verify that the sensor provides stable pulses without sudden jumps or drops. Electronic pickup systems should respond smoothly to rotor movement. A small sample test at different flow points helps confirm this.

Burak’s turbine gas meters use well-tested signal systems that keep output steady across changing conditions.

6. Assess Pressure and Temperature Compensation Options

Some applications require compensation features to maintain accurate readings during pressure or temperature shifts.

Check whether the meter supports built-in or external compensation. This feature helps maintain correct readings if process conditions vary.

Not all meters need compensation, but it helps if your system faces regular variation.

7. Compare Manufacturer Test Procedures

A reliable turbine manufacturer follows clear test standards. Ask for details of the test bench, instruments, and methods used for calibration. A strong process includes flow tests at several points, repeat runs, and a detailed report.

Burak Metering follows industry-acceptable test steps and shares results openly, making them one of the leading turbine gas meter manufacturers in India.

Read their guidance on how to choose the right turbine gas meter for your application to support your selection.

Discuss your flow conditions with Burak engineers for correct meter testing and selection.

8. Review Warranty and Service Support

A strong warranty shows confidence in product stability. Check coverage for manufacturing defects, electronics, and mechanical parts. Service support should include calibration help, spare availability, and after-sales assistance.

Burak Metering provides dependable support, explained in turbine gas meter warranty and service, which helps buyers compare manufacturers with clarity.

Connect with Burak today to review warranty terms before your next purchase.

Contact Us

Burak Metering stands among the top gas flow meter manufacturers in India. Our meters follow strong engineering practices, verified calibration steps, and consistent build standards.

Buyers choose us because the company offers steady performance, reliable service, and long operational life across many industries.

Reach out to us for high-accuracy turbine gas meters supported by dependable testing and customer assistance.