- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

How Pressure & Temperature Impact Turbine Gas Meter Accuracy in India

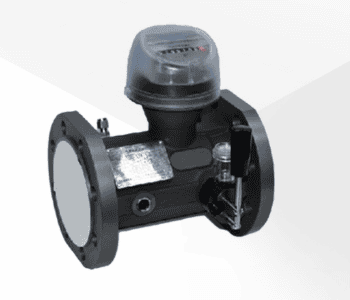

A turbine gas meter records how fast a gas stream spins a rotor. The rotor speed links to gas velocity and flow rate. Gas meters must deliver accurate volume readings for billing, safety, and process control. Pressure and temperature affect gas volume and density. Gas law formulas are needed to convert measured volume to a base volume.

In industrial settings, Burak turbine gas meters help customers get accurate flow data. Burak is a leading turbine gas meter manufacturer in India.

How Temperature Affects Gas Flow Measurement

Temperature changes the size and spacing of gas molecules. When gas warms, molecules move faster. This movement lowers gas density. Cooler gas slows molecules and raises density. A turbine meter counts volume but the volume of warmer gas is larger than the same mass of cooler gas. This creates errors if not corrected.

In turbine meters, temperature affects the rotor and bearings too. Heat can expand metal parts slightly. Expansion changes internal clearances. This change may alter the rotor speed versus volume relationship. Cold may contract parts and slow rotor response. For accurate output, meters often include temperature sensors. These sensors feed into correction algorithms that adjust flow readings.

Gas law relationships show that a small error in temperature sensing causes a proportional error in base volume. A common rule from industry studies is that a one-degree Fahrenheit error gives about 0.2% error in converted gas volume.

How Pressure Affects Gas Flow Measurement

Pressure pushes gas molecules closer together. Higher pressure increases gas density. Lower pressure reduces density. Turbine meters count volume at the operating pressure. To compare results across systems or standards, users must convert to a base (standard) pressure.

High pressure makes the same volume contain more gas mass. Without correction, meters may underreport or overreport the amount of gas passing through. Meter performance tests show that pressure changes influence the Reynolds number of the flow. At low pressure and low flow, errors increase. At higher pressure and flow, the meter behaves more predictably.

Pressure also affects the meter hardware. Extreme pressure can slightly deform internal parts. Even small dimensional changes can change the flow profile inside the meter and shift calibration. Meter makers and system designers must consider the expected pressure range when selecting a turbine meter.

Burak turbine gas meters include pressure taps and correction modules to deliver consistent measurements in industrial pipelines.

Why Correction for Temperature and Pressure Matters

Natural gas and other gases are compressible. Volume depends on both pressure and temperature together. Conversion formulas use gas law equations to compute a “standard volume” that customers and systems agree on.

Without correction:

- Two identical meters in different climates may show different totals.

- Billing based on raw meter counts may be unfair.

- Process control systems may misinterpret flow rates.

With correction:

- Readings reflect how much gas would flow at a chosen base condition.

- Billing and system control are consistent across sites.

Partner with Burak Metering for turbine gas meters with built-in pressure and temperature compensation systems.

Real-World Impact: Industrial Gas Flow Challenges

In India, industrial operators must manage gas delivery under varying conditions. Weather swings from hot summer to cool winter. Pipeline pressure can change with demand and compressor stations. Turbine gas meters must handle these shifts and still report accurate flow data.

Burak turbine gas meters are built for rugged industrial use in India. They include:

- Temperature sensors for real-time compensation

- Pressure taps for base volume conversion

- Calibration options for local operating conditions

These features help industrial users avoid costly errors and maintain compliance.

Installation, Calibration, and Best Practices

Precision measurement requires correct installation of turbine gas meter. Following meter manufacturer guidelines keeps sensing points accurate. Placing temperature and pressure sensors at the correct points in the meter run gives better correction.

Routine calibration under expected operating conditions maintains accuracy over time. Pressure and temperature compensation should match the range the meter will see in service. Operators should check sensors periodically to catch drift before it affects billing or control data.

Contact Burak’s engineering team for guidance on site setup and calibration services.

Contact Us

Burak Metering is a top gas flowmeter manufacturer in India.

Our team makes turbine gas meters with high accuracy and field-ready performance. We help customers select the right meter and install it for best results.

Burak supports your projects with engineering guidance, calibration advice, and service.

For a reliable turbine gas meter and expert help, reach out to Burak today.