- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

How Often to Calibrate Your Turbine Gas Meter?

TL;DR

- Turbine gas meters typically need calibration once a year, but critical sites may need it more often.

- The calibration interval depends on usage, drift, environment, and manufacturer guidelines.

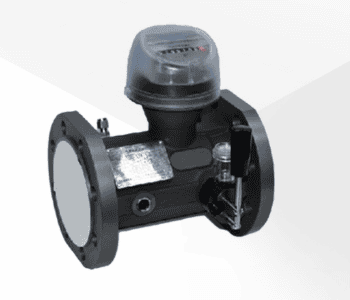

Turbine gas meters measure gas flow by counting rotor spins. Over time, bearings wear, gas properties shift, or sensor drift may emerge. These changes affect accuracy. Regular calibration keeps measurements reliable.

For users of Burak Metering’s turbine gas meters, understanding calibration needs saves cost and supports trust in billing, safety, and operations.

→→ Turbine Gas Meters: Working to Application

Why Calibration Matters

- Accuracy Maintenance

Over long use, rotor wear, blade damage, or sensor drift can shift the meter reading. Calibration finds and corrects that drift. - Regulatory Compliance

Many industries demand flow-meter calibration. Inaccurate meters can lead to billing losses or safety risks. - Traceability

Calibration done by a lab with national standards (for example, Burak's gas flow meter calibration service) ensures that your meter’s performance is verified against certified references. - Longer Meter Life

Regular calibration helps you detect mechanical wear early and plan maintenance. That extends the lifetime of your turbine gas meter.

How Often to Calibrate a Turbine Gas Meter

Manufacturer Recommendation

Follow the calibration schedule recommended by the meter maker. This is the baseline.

→→ Frequent Turbine Gas Meter Setup Issues and How to Prevent Them

Industry Guidance

- Flow-meter calibration guides recommend once a year for many industrial turbine meters.

- In critical or custody-transfer applications, you may need calibration every 6 months, or even more often if risk is high.

- According to regulatory or internal risk-based policies, intervals could be shorter.

Monitoring Drift

- After you do your first calibration, chart the meter’s error over time. If the meter drifts close to 80% of error tolerance by the end of the interval, you should shorten the interval.

- If drift remains small, you can keep the same interval.

Risk-Based or Condition-Based Approach

- Use risk assessment: critical metering or high-value gas flows → more frequent calibration.

- Use condition monitoring: check for rotor drag, bearing wear, or signal issues.

- In some systems, you may calibrate more often after repair, relocation, or process changes.

Best Practices for Calibration of Turbine Gas Meter

- Use the Same Medium

Calibrate with gas similar to your process—pressure, composition, temperature should match your operating conditions. - Use Traceable Standards

Use an accredited lab or reference meter that traces to national standards. - Multiple Flow Points

During calibration, test the meter at several flow points (for example 10%, 25%, 50%, 75%, 100%) to verify linearity. - Stabilize Before Recording

Let the flow stabilize before taking readings. Sudden surges or turbulence can distort results. - Record and Document

Maintain a calibration log. Record dates, flow points, deviations, and corrective actions. - Review Annually

Even if meter seems stable, review the calibration data annually. Look for trends of drift.

When to Calibrate More Often

You may need to calibrate more than once a year if:

- The gas meter is part of custody-transfer accounting. In these cases, small errors have big financial impact.

- Operating conditions change (pressure, gas mix, temperature).

- There is mechanical wear: rotor drag, bearing noise, or rotor slowdown.

- After maintenance, repair, or relocation of the meter.

- Internal audits or quality requirements demand tighter accuracy intervals.

Why Burak Metering Is a Top Choice for Calibration of Gas Meters in India

Burak Metering is one of the leading turbine gas meter manufacturers in India. We design meters to maintain stable calibration over long periods. Our meters:

- Use high-grade components to reduce mechanical drift.

- Are backed by calibration support and documentation.

- Meet national and international standards.

- Benefit from Burak’s deep metrology expertise and after-sales service.

If you use a Burak turbine gas meter, you can trust its performance and rely on our team to guide your calibration schedule.

If you want precise, reliable turbine gas meters, Burak Metering is your partner.

We are a top gas meter manufacturer in India. We deliver meters that retain accuracy, and we support calibration planning.

Contact us today for a consultation, calibration advice, or to order your next turbine gas meter.

Trust Burak’s experience, quality, and service to help you measure gas flow with confidence.