- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Mechanical or Electronic Turbine Gas Meter? Best Choice for Indian Plants

TL;DR

- Mechanical meters give simple operation and lower cost.

- Electronic meters give higher accuracy and digital output.

- Indian plants should choose based on precision needs, monitoring style, and long-term workflow.

Indian industrial gas users handle natural gas, biogas, PNG, CNG, and LPG across varied environments. Many plants depend on turbine gas meters to record flow with steady performance.

The two main options

- mechanical turbine gas meter

- electronic turbine gas meter

both meters work on the same turbine rotation principle but differ in accuracy, ease of reading, data output, and long-term advantages.

This blog compares both types using simple, clear statements so you can decide which meter fits your pressure rating, line size, and monitoring method.

How Mechanical Turbine Gas Meters Work

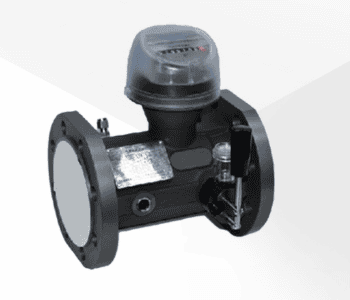

Mechanical turbine gas meters measure flow using a rotating turbine that moves in direct contact with gas. Gears and dials display the reading. The system stays steady through a basic mechanical link between the turbine and the counter. This style remains common across gas distribution, boilers, furnaces, and plant utility zones.

Key Points

- Works without power supply

- Shows readings on a dial

- Lower upfront cost

- Simple servicing with basic tools

Mechanical meters remain common in India because they support stable plant conditions and allow field teams to check readings quickly during routine rounds.

How Electronic Turbine Gas Meters Work

Electronic turbine gas meters follow the same turbine rotation method but use sensors to convert turbine speed into digital signals. A processor calculates flow rate, total volume, and compensated values if the model supports temperature and pressure inputs.

Key Points

- Provides digital output

- Supports SCADA and PLC integration

- Gives finer measurement detail

- Reduces manual checking

Electronic meters suit Indian industries that track flow charts, require remote visibility, or depend on real-time data for billing, load planning, and safety control.

For anyone researching turbine gas meters, resources such as

act as helpful guides for users exploring how turbine measurement systems operate.

Mechanical Meter Advantages

Mechanical meters stay relevant due to their simple build and reliable performance. Many Indian users choose them for locations where power access is limited or where a physical display is helpful for staff.

Benefits

- Lower cost

- Easy reading

- Good for steady flow

- Strong metal housing

Plants that run basic utilities often use mechanical meters in zones where flow does not change rapidly.

Electronic Meter Advantages

Electronic meters offer higher precision and automated reporting. Many Indian plants move to digital meters because they reduce manual rounds and give faster insight into flow variations.

Benefits

- Strong accuracy across wide ranges

- Digital communication for plant systems

- Logs flow patterns

- Supports alerts for drift or wear

This reduces common errors in manual reporting and supports compliance for audited gas consumption data.

Which Meter Has Better Long-Term Value?

Mechanical meters cost less early. Electronic meters cost more but reduce long-term effort because they reduce manual checks and give clearer data. Many Indian industries now prefer electronic versions for this reason, especially in continuous operations.

Mechanical meters remain useful where conditions are stable and reading does not need constant system integration.

Electronic meters fit plants that track flow tightly, bill customers, or adjust burners based on gas availability.

Accuracy Comparison

Mechanical meters maintain good accuracy at stable flow but may shift slightly due to wear.

Electronic meters track low and high flow rates with better sensitivity, giving more reliable output in situations where reporting matters, such as CNG stations, power plants, and pipeline custody points.

Application Fit for Indian Industries

- Mechanical Meters:

Useful for boilers, furnaces, kilns, textile dryers, and standard process lines. - Electronic Meters:

Better for SCADA-based plants, gas distribution networks, CNG stations, and places that need reliable automated logs.

Many Indian users combine both. Mechanical meters act as field-ready units. Electronic meters cover control points.

Final Decision: Mechanical or Electronic?

Mechanical turbine gas meters are better for simple monitoring and low-budget setups.

Electronic turbine gas meters are better for precise measurement, data-driven operations, and remote visibility.

Indian plants should choose based on process demand, accuracy needs, monitoring style, and long-term cost planning.

Why Burak Is the Right Choice

Burak Metering is a leading manufacturer of turbine gas meter in India. Each unit follows strict testing steps that help maintain stable performance in diverse Indian operating conditions.

The product range supports multiple line sizes, pressure classes, and gas types used across manufacturing, distribution, and commercial sectors.

Customers choose Burak for consistent meter quality, responsive support, and dependable delivery, making it one of India’s leading gas flow meter manufacturers.

We offer strong service, dependable product quality, and long-term reliability. If your facility requires stable turbine gas meter performance, contact us now for quick quote.