- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

How Gas Flow Impacts Turbine Gas Meter Rotation and Accuracy?

TL;DR

- Gas flow controls rotor speed and directly affects turbine meter accuracy.

- Stable, clean, and aligned flow helps produce reliable readings.

- Correct meter choice and good installation protect long-term performance.

Gas flow decides how fast a turbine gas meter rotates and how accurate the readings remain. The rotor movement depends on gas speed, pressure, density, and flow pattern. Even small changes in these conditions can shift measurement output.

This blog explains the impact of gas flow on turbine rotation in a clear and simple style suited for Indian users and search engines.

How Gas Flow Starts Rotor Movement in Turbine Gas Meter

Gas enters the inlet and pushes the blades. The stream carries energy, and this energy forces the rotor to turn. Fast flow creates quick rotation. Slow flow creates slower rotation. This direct link forms the basic working principle of every turbine meter.

A stable stream gives a balanced force on each blade. Disturbed gas creates uneven pressure on the rotor, which may shift the reading.

Flow Speed and Turbine Meter Response

Gas speed influences how smoothly the rotor of the turbine gas meter moves. Steady flow keeps the blades rotating at a predictable rate. Sudden changes can cause slight irregular movement. These small shifts affect the pulse signal used for the final reading.

A good pipeline layout helps maintain a stable gas speed. Straight pipe sections before the meter keep the stream aligned.

Impact of Pressure and Temperature on Turbine Gas Meter

Gas pressure changes the force delivered to the blades. High pressure provides more energy and increases rotation. Low pressure gives a weaker force and lowers rotor speed.

Temperature changes density. Denser gas carries more momentum and rotates the blade with a stronger force. Hotter gas carries less density, reducing blade push. Many Indian industries face daily temperature swings, making steady operating conditions helpful for accuracy.

Mechanical Resistance and Clean Gas

Friction inside the meter can slow the rotor. Worn bearings or dirt in the meter body add resistance. Even small dirt particles affect movement over time.

Clean gas protects the internal components. Filters reduce solid debris, moisture, and oil traces. This helps maintain accuracy and supports long service life.

Flow Profile and Alignment of Turbine Gas Meter

A centered gas stream gives the blades equal force. A misaligned or disturbed flow touches only part of the rotor path. This creates imbalanced turning and changes the output signal.

To keep the flow straight, installers use proper pipe length before the meter. This simple step reduces turbulence in many Indian industrial setups.

Gas Purity and Long-Term Accuracy in Turbine Gas Meter

Particles and droplets behave differently from clean gas. When they strike the blades, they cause sudden, small force spikes. Over time, these spikes change rotation smoothness.

Moisture and dirt can stick to internal surfaces. This reduces space for free rotation and creates drag. Good filtration improves meter life and reading stability.

Choosing the Right Turbine Gas Meter for the Right Flow

Correct meter selection supports stable performance. Oversized meters rotate too slowly at low flow. Undersized meters may reach the limit during high flow.

Mechanical and electronic turbine meters handle rotation signals differently. A simple guide comparing both types is here: Mechanical or Electronic Turbine Gas Meter? Best Choice for Indian Plants and Turbine Gas Meters: Working to Application

Installation Conditions That Affect Rotor Movement

Sharp pipe bends, quick valve openings, and compressor pulsations disturb gas flow. These factors often appear in many Indian gas lines. Each disturbance changes how the blades receive force.

Correct installation helps avoid these issues. Straight runs, smooth transitions, and stable inlet conditions are easy improvements for better output.

Maintenance for Better Accuracy

Regular checks keep the meter performing well:

- Remove dirt or buildup

- Inspect bearings for wear

- Verify calibration

- Confirm smooth rotor movement

These steps help maintain consistent readings even in demanding environments.

Why Gas Flow Matters in Every Turbine Meter

Gas flow sets the movement pattern of the rotor. Flow speed, pressure, temperature, purity, and flow profile combine to shape rotation. Stable flow leads to steady rotation. Steady rotation leads to better accuracy. A planned setup and correct meter choice help industries measure gas with confidence.

Contact Us

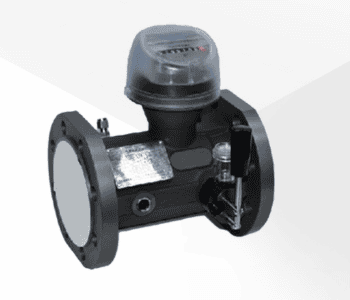

Burak is a top turbine gas meter manufacturer in India that delivers consistent performance, strong accuracy, and long service life.

Our products match the needs of Indian industries that depend on stable and dependable readings. Companies choose Burak because of our quality focus, reliable build standards, and helpful customer support.

For clear guidance and dependable gas flow measurement, reach out to us today.