- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Understanding Turbine Flow Meter & How to Choose the Best One

A Turbine flowmeter is a widely used device for flow measurement of a liquid and gaseous fluid in industries like oil & gas, water treatment, pharmaceuticals, and manufacturing.

It works on the Mechanical rotation principle. A rotating turbine is placed into the flow path of the turbine flowmeter, whose speed is proportional to the fluid velocity.

In this blog, we will detail the working principle, key components, advantages, limitations, and factors to consider when selecting a Turbine flowmeter.

These aspects will help you in choosing the right flowmeter and ensure accurate measurement.

Working principle of Turbine Flow Meter

A Turbine flowmeter operates on a simple yet highly effective principle I.e. Mechanical rotation

It measures the flow rate of liquids or gases by detecting the rotational speed of the turbine rotor, which is placed inside the flow stream of the flowmeter.

The faster the fluid or gas moves through the turbine rotor, the faster it spins. This rotational speed is then used to determine the flow rate.

Here’s a step-by-step breakdown of how a turbine flow meter works:

- Fluid Enters the Meter

- The process begins when the liquid or gas flows into the pipe.

- As it passes through the flowmeter, which contains a multi-bladed turbine rotor, the fluid forces the turbine to spin.

- Turbine Rotation

- As the fluid moves, it transfers kinetic energy to the turbine blades, causing them to spin.

- The rotational speed of the turbine is directly proportional to the velocity of the fluid; a higher flow rate makes the turbine spin faster, while a lower flow rate slows it down.

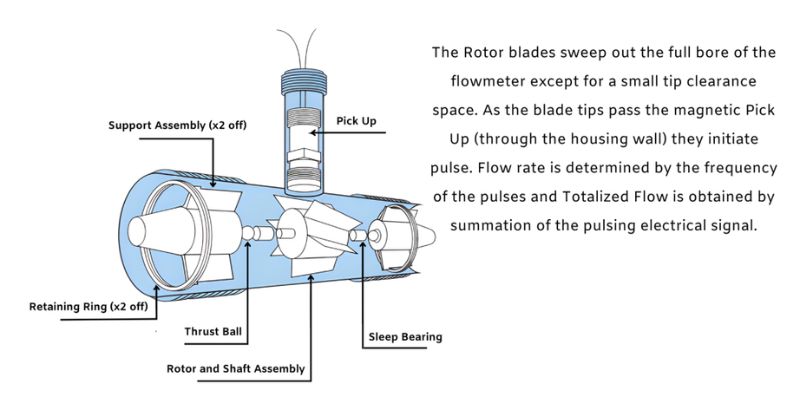

- Magnetic or Optical Sensing of Rotational Speed

- As the turbine blades pass the sensor, they create pulses (electrical or optical signals).

- The frequency of these pulses corresponds to the turbine's rotational speed, which is then used to calculate the flow rate.

Key Considerations for Accurate Measurement

- Straight Pipe Requirements: To ensure laminar and uniform flow, a Turbine flowmeter typically requires an upstream and downstream straight pipe section, which helps minimize turbulence.

- Fluid Properties: The Turbine flow meter works best with clean, low-viscosity, non-corrosive fluids. Particulate matter, bubbles, or high-viscosity liquids can affect accuracy and damage the rotor.

- Temperature and Pressure Limits: Ensure that your flowmeter’s materials and design can withstand the liquid's temperatures and pressures.

Key Components of a Turbine Flow Meter

A turbine flow meter includes several critical components:

- Rotor blades that spin with fluid flow

- Shaft and bearings to support the rotor

- Pickup sensor to detect blade movement

- Signal converter to translate pulses into readable data

- Digital or analog display to show flow rate

- Protective housing with proper inlet/outlet connections

In digital models, the system often includes communication protocols like Modbus or HART for integration with industrial control systems.

A digital turbine flow meter also provides enhanced data logging, remote monitoring, and real-time alerts.

Accuracy and Installation Considerations

Accuracy depends on several factors: sensor sensitivity, fluid type, temperature, and pipeline conditions. Clean, low-viscosity fluids yield the best results.

Straight pipe runs, typically 10 diameters upstream and 5 downstream, help reduce turbulence, which can impact readings.

Proper calibration using the manufacturer’s K-Factor ensures reliable measurements.

For gases, using a natural gas turbine flow meter or turbine gas meter built for the specific application is essential.

Turbine flow meters are not ideal for slurries, steam, or fluids with high particulate matter, as these can damage the rotor or skew results.

They should also be installed away from valves or elbows to prevent distorted flow profiles.

Discover high-precision inline turbine flow meters for your industry.

Contact Burak Metering for turbine flow measurement solutions.

Industrial Applications of Turbine Flow Meters

Turbine flow meters are widely used across multiple industries due to their high accuracy, fast response time, and compatibility with a wide range of fluids and gases. These meters offer dependable volumetric flow measurement, making them ideal for both liquids and gases under steady, clean flow conditions.

1. Oil and Gas Industry

Turbine flow meters play a critical role in the oil and gas industry, especially in applications like:

- Custody transfer of natural gas in pipelines: High-precision measurement is essential for billing between suppliers and customers. Turbine meters, combined with electronic volume correctors (EVCs), allow for pressure and temperature-compensated readings.

- Crude oil measurement: Refineries use turbine flow meters to measure the flow of crude oil and processed products for internal monitoring and sales.

Their reliability and accuracy make them well-suited for custody transfer, regulatory compliance, and production monitoring.

2. Chemical Industry

Turbine flow meters are widely adopted in chemical plants for:

- Accurate flow measurement of process gases and liquids to ensure consistent dosing and mixing.

- Preventing waste and ensuring system balance by delivering real-time data.

- Measuring the flow of corrosive or hazardous chemicals when paired with suitable materials of construction.

Turbine meters support safe and efficient chemical operations, especially in batch and continuous processing environments.

3. Power Plants

In power generation plants, turbine flow meters are used to:

- Measure combustion air and fuel gas to optimize burner performance.

- Support emissions reduction by maintaining ideal combustion ratios.

Accurate measurement ensures efficient energy usage and helps maintain compliance with environmental regulations.

4. Compressed Air Systems

Compressed air is a vital utility in many industries. Turbine flow meters help monitor:

- Compressed air consumption at various points in the distribution network.

- Leak detection and efficiency improvements by pinpointing usage anomalies.

- Overall energy management for large-scale systems.

Their ability to handle high flow rates makes them ideal for industrial compressed air applications.

5. Water and Wastewater Treatment

In **water treatment plants**, turbine flow meters are used to:

- Measure flow in treated water distribution and wastewater discharge.

- Ensure correct flow rates for chemical dosing and filtration.

- Monitor system efficiency and prevent water loss.

Turbine meters help maintain operational stability and regulatory compliance in municipal and industrial water treatment.

6. Food and Beverage Industry

In the food and beverage sector, turbine flow meters provide precise flow control for:

- Liquid ingredients like syrups, oils, milk, and juices are used during mixing and processing.

- Ensuring accurate bottle and can filling operations.

- Maintaining consistency in product quality across batches.

Hygienic turbine meters with sanitary designs are commonly used in this industry to meet food safety standards.

7. Pharmaceutical Industry

Precision is essential in the pharmaceutical industry, and turbine meters are used to:

- Monitor fluid flow in mixing and formulation processes.

- Maintain tight control over ingredient volumes in batch production.

- Ensure compliance with quality control standards.

Stainless steel and sanitary-grade turbine meters are often selected to meet the strict hygiene and validation requirements in pharma operations.

8. Biogas and Flare Gas Monitoring

Turbine gas flow meters are applied in biogas plants, landfills, and flare gas systems for:

- Monitoring biogas production to evaluate system efficiency.

- Measuring flare gas emissions to support environmental reporting and regulatory compliance.

- They operate reliably in aggressive or contaminated gas environments due to their rugged design.

Benefits of Turbine Flowmeter

High Accuracy

Turbine meters provide precise readings, making them ideal for custody transfer, dosing, and process control.

Fast Response Time

They respond quickly to changes in flow rate, supporting real-time monitoring in dynamic systems.

Wide Flow Range

Turbine flow meters handle a broad spectrum of flow rates without compromising measurement accuracy.

Low Pressure Drop

These meters are engineered for minimal flow resistance, helping maintain system efficiency and reduce energy loss.

Versatile Applications

Suitable for both gas and liquid flow measurement, including compressed air, natural gas, water, chemicals, and more.

Durable Construction

Built with strong materials, turbine meters are reliable in harsh environments and offer long service life with proper maintenance.

Integration-Ready

They support electronic volume correctors (EVCs) and industrial monitoring systems for advanced flow data management and compensation for pressure and temperature.

Cost-Effective

Turbine flow meters provide a balance of accuracy, performance, and affordability, making them a practical choice for many industries.

Limitations of Turbine Flowmeter

- It is not suitable for dirty or viscous fluids, particles like debris, or thick fluids, which can damage the turbine blades and affect its accuracy.

- It is not ideal for highly corrosive chemicals

- It requires a straight pipe to ensure accurate flow measurement

- Swirling flows, pressure changes, or vibrations in the pipeline can reduce its accuracy.

Choose the Right Turbine Flowmeter for Your Needs

- Identify your fluid type and determine if it is liquid or gas. thick or thin? clean or contaminated? because turbine flowmeters work well with clean and less viscous fluids.

- Check the flow range of your flow meter. Turbine flowmeters won't spin if the flow is too low, and they may wear out fast if the flow is high.

- Look at your pipe size as the diameter of your pipeline matters; choose the flowmeter that matches your pipe size.

- Do consider the temperature, pressure, and viscosity of the fluid.

- Turbine flowmeters need a straight pipe section; thus, make sure you have enough space for turbine meters.

- Various types of flow meters provide analog or digital output; choose the one that best suits your needs.

- Turbine flowmeters have moving parts that wear out over time. So, pick a model that is easy to clean, repair, and calibrate.

- Last but not least, here I would recommend that you don't just go out for the cheapest option. A high-quality flowmeter might cost you more upfront, but it will save you money in the long run with better durability and accuracy.

Conclusion

Now you must have understood that a Turbine flowmeter is a reliable and accurate tool for flow measurement in various industries.

If you are planning to buy a Turbine flowmeter and need expert guidance, you can consider Burak Metering. We are a leading manufacturer of turbine flow meters in India.

Get in touch with us today and find the best flow measurement solution for your industry!