- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Where Turbine Gas Meters Play a Major Role in Indian Industries

TL;DR

- Turbine gas meters support Indian industries with precise flow measurement and steady operation.

- They serve steel plants, ceramics, food processing units, CGD networks, and more.

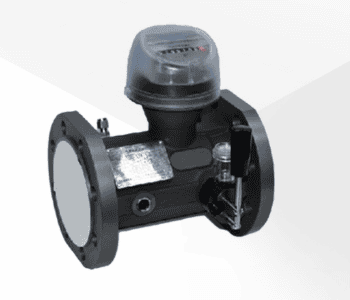

Turbine gas meters play a key role in India’s growing industrial energy network. These meters measure gas flow with steady accuracy, support safe operations, and help companies maintain clear consumption records.

Many Indian facilities prefer this technology because it offers steady performance, long service life, and simple maintenance needs.

To learn more about functioning and benefits of turbine gas meter: Turbine Gas Meters: Working to Application.

1. City Gas Distribution Networks

City gas distribution networks use turbine gas meters to measure flow at district stations, industrial lines, and commercial points. These meters offer steady readings even during sudden flow variations. Indian cities with active expansion plans rely on them for accurate billing, pipeline balance, and pressure control.

Gas distributors prefer turbine gas meters at receiving terminals and load transfer stations because the equipment responds well to medium and high flow ranges. Integration with digital systems is simple, which helps control rooms retrieve consumption data quickly. These advantages help CGD operators run safe and stable networks.

2. Steel, Forging, and Metal Processing Plants

Steel and forging units in India depend on controlled heat requirements. Turbine gas meters help plants measure natural gas consumed by reheating furnaces, cutting lines, and heat-treatment operations. The compact build and low pressure drop feature support seamless furnace feed.

Many metal units record consumption for each furnace bay. Precise readings help avoid wastage and allow better load planning. Plants that run multiple gas-fired stations use centralized monitoring systems, where turbine gas meters act as the primary input devices. Their sturdy internal rotor makes them suitable for long operating cycles found in metal industries.

3. Ceramic, Glass, and Brick Manufacturing

Ceramic and glass industries rely on stable flame levels to produce consistent output. Turbine gas meters support this requirement with smooth measurement patterns across wide temperature environments. Indian ceramic clusters, especially in Gujarat and Rajasthan, install these meters on kiln lines to track gas use during heating, soaking, and cooling phases.

Brick manufacturing units that adopt gas-based firing systems also use turbine meters to replace manual monitoring. Automated data logging brings better control over batch cycles, which improves production planning and energy cost calculation.

4. Food Processing and Dairy Plants

Food and dairy industries need accurate flow control for ovens, dryers, boilers, and direct-fire equipment. Turbine gas meters provide clean measurement without interrupting the flow, which supports hygiene and maintains process stability.

Dairy units using gas-based spray dryers record significant improvements in cost control when switching to turbine meters. Food factories benefit from the meter’s ability to handle varied flow patterns, especially during peak production hours. Central control rooms use this data to maintain consistent heating cycles.

5. Textiles and Dyeing Facilities

Gas-fired stenters, dryers, and boilers in textile units require uninterrupted flow measurement. Turbine gas meters support these operations with stable output under shifting load patterns. Indian dyeing houses appreciate the device’s ability to stay reliable across long shift cycles.

Energy management teams track meter readings for cost allocation across multiple departments. Turbine gas meters also integrate well with digital dashboards, helping units improve resource control.

6. Petrochemical and Refinery Segments

Petrochemical plants and refineries handle gas streams that demand precision. Many facilities use turbine gas meters at internal distribution lines to monitor consumption used for burners, heaters, and process reactors. The low maintenance structure supports long intervals between service checks.

Safety teams rely on accurate flow readings to maintain acceptable operating limits. The rugged structure of turbine meters supports them in environments where pressure and temperature fluctuate often.

7. Power Generation and Captive Plants

Gas-based power units, including turbine-driven generator farms, use turbine gas meters to track fuel intake. These readings help maintain plant efficiency and support compliance reporting.

Captive power units in commercial parks and industrial estates often install turbine meters because they can manage high flow capacity. Data from these meters also helps energy teams optimize load distribution.

8. Pharmaceuticals and Chemical Production

Pharmaceutical plants and chemical units depend on precise heating stages during formulation and drying cycles. Turbine gas meters offer reliable output without introducing noise into the control system.

Chemical reactors that consume gas in stable patterns benefit from the meter’s quick response time. Production managers use meter data to match batch records with consumption charts, which supports operational transparency.

9. Heavy Engineering and Machinery Fabrication

Large manufacturing units use gas-fired cutting tools, pre-heating bays, and paint curing systems. Turbine gas meters help track gas supply across these varied applications. Their simple internal design means plants can maintain them without frequent shutdowns.

Data generated by turbine gas meters helps engineering firms plan operating budgets more effectively. These meters also support automated line monitoring, which is vital for large facilities.

10. Commercial Kitchens and Hospitality Chains

Large kitchens in hotels, resorts, and catering businesses use turbine gas meters to track consumption for ovens, burners, boilers, and heating equipment. Gas flow varies sharply in these environments, but turbine meters adjust well to these shifts.

Large food service chains adopt turbine gas meters to standardize energy cost analysis across multiple properties. Accurate readings help them avoid billing disputes and improve overall planning.

Interested in comparing mechanical and electronic versions of turbine gas meter? Check Mechanical or Electronic Turbine Gas Meter? Best Choice for Indian Plants

Why Turbine Gas Meters Remain a Strong Choice in India

Industrial buyers in India continue to adopt turbine gas meters for three clear reasons:

- Consistent measurement

- Wide operating range

- Long service life.

These factors allow companies to run safe, efficient, and energy-conscious operations across every major sector.

Contact Us

Burak Metering is a leading turbine gas meter manufacturer in India. We focus on accuracy, dependability, and clean construction. Each meter passes strict quality checks, helping customers achieve stable performance in demanding environments.

Industries prefer us because we offer reliable support, proven field experience, and modern manufacturing standards. These strengths position Burak as a top turbine gas meter manufacturer in India.

For clear guidance and dependable gas flow measurement, contact us today.

Email: sales@burak.in

Phone: +91-8655587403