Working Principle of Thermal Mass Flow meter

The working principle of a thermal mass flow meter is based on the concept of heat transfer and the cooling effect caused by the flow of a gas or fluid. Here's a step-by-step explanation of how a thermal mass flow meter operates:

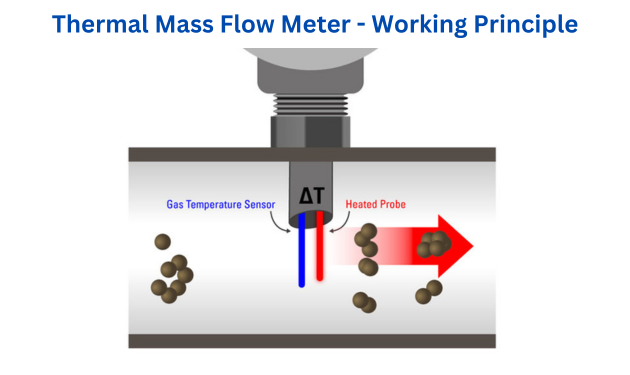

Sensor Element: The core component of a thermal mass flow meter is the sensor element. This element typically consists of two temperature sensors: a heated sensor (the mass flow sensor) and an unheated sensor (the reference sensor). Both sensors are positioned in the flow stream.

Heating the Mass Flow Sensor: The heated sensor is designed to maintain a constant temperature higher than the measured fluid or gas. It is heated using a small heating element.

Measuring Temperature Difference: As the gas flows through the meter, it carries heat away from the heated sensor. The unheated reference sensor measures the actual temperature of the gas. The difference in temperature between the heated sensor and the reference sensor is directly proportional to the mass flow rate of the gas.

Calculation: The meter's electronic circuitry calculates the flow rate based on the temperature difference between the two sensors. This calculation uses specific algorithms or calibration data considering sensor characteristics and gas properties.

Output: The calculated mass flow rate is typically displayed digitally or transmitted as an analog or digital signal for monitoring and control.

A thermal mass flow meter measures the flow of gases by heating one of its sensors and monitoring the temperature difference between the heated sensor and the reference sensor. The cooling effect caused by the flowing gas results in a temperature differential that is directly related to the mass flow rate and this relationship is used to calculate and output the flow rate information. This method provides a highly accurate and reliable means of measuring gas flow, particularly in applications where precision is crucial.