Working Principle of Electromagnetic Flow Meter

The working principle of an electromagnetic flow meter revolves around Faraday's law of electromagnetic induction, which establishes a relationship between a magnetic field, the velocity of a conductive fluid, and the induced voltage.

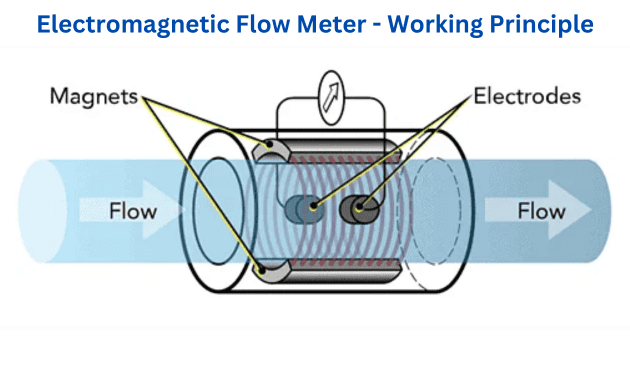

Magnetic Field Generation: The flow meter consists of a non-conductive pipe through which the conductive liquid flows. Inside the pipe, two electrodes are placed perpendicular to the flow direction. A magnetic field is generated by passing a low-frequency current through these electrodes.

Flow of Conductive Fluid: As the conductive fluid moves through the pipe, it passes through the magnetic field generated by the electrodes.

Induced Voltage: According to Faraday's law of electromagnetic induction, when a conductive fluid moves through a magnetic field, it generates a voltage perpendicular to the magnetic field and the fluid's velocity. This induced voltage is directly proportional to the velocity of the liquid.

Electrode Detection: The electrodes within the flow meter are designed to detect this induced voltage. They pick up the voltage signal generated by the movement of the conductive fluid through the magnetic field.

Measurement and Calculation: The detected voltage signal is proportional to the flow velocity of the liquid. The flow meter's transmitter processes this voltage signal and converts it into a flow rate measurement. The flow rate of the conductive liquid passing through the pipe is accurately determined by calibration and further processing.

Output Display: The calculated flow rate data is typically displayed on the meter's screen or sent to external systems for monitoring or control purposes.

This principle effectively measures conductive liquids' flow, providing accurate and reliable flow rate readings. However, it's important to note that non-conductive or low-conductivity fluids might not yield accurate results with this type of flow meter. Also, proper installation and maintenance are essential to ensure accurate readings.

Electromagnetic flow meter manufacturer in India, Electromagnetic flowmeter supplier in Punjab, Electromagnetic flow meter manufacturer in Gujarat, Magnetic flowmeter manufacturer in Delhi, EM Flowmeter in India, Electromagnetic flow meter in Chennai, Magnetic flowmeter in Goa