Phone

Phone

Vortex flow meters have become a key tool in industries that require accurate and reliable flow measurements. From oil and gas to water treatment plants, these meters are used to measure the flow of liquids, gases, and steam.

By measuring the vortices created as fluid flows around a small obstruction, vortex flow meters can accurately determine flow rates without the need for moving parts.

This results in less wear and tear, leading to lower maintenance costs and an extended operational life. Vortex meters are not only dependable but also offer a versatile solution for high-temperature and high-pressure applications.

In this blog, we will look at the what is vortex flow meters, different types of vortex flow meters, their benefits and drawbacks, and where they are used.

By the end, you’ll get a better understanding of these important devices and how they help keep operations running smoothly.

Seeking the ideal vortex flow meter for your specific application?

These flow meters measure the vortex flow by creating tiny swirling patterns (vortices) in the fluid as it passes a small obstruction (called a bluff body) inside the pipe. Then the flow meter counts how often the vortices are created, and these vortices help to calculate the flow rate.

These meters do the same thing as the standard vortex meters, but they can measure several things simultaneously. In addition to flow rate, they measure both pressure and temperature; that is quite a lot in one meter.

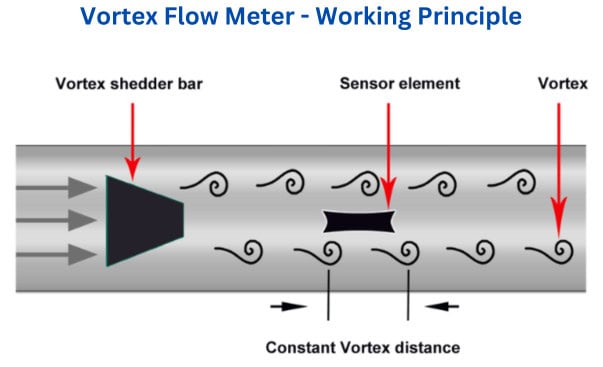

The Vortex flow meters operate on the principle of the Von Karman effect, which involves the generation of vortices when a fluid flows past a bluff body (such as a triangular or rectangular bar) inserted into the flow path.

Here’s how does vortex flow meter works?

A small body or object (called a bluff body) is strategically placed inside a meter body. As the fluid flows past this object, it creates swirling patterns called vortices on both sides of the object. The faster the fluid moves, the more frequently these vortices are created. The frequency of vortices helps to measure the flow rate

Vortex shedding is when a fluid flows around an object and produces small swirling patterns behind it. It is termed vortex shedding. These swirls are known as vortices, and they are generated on both sides of the object. The faster the fluid moves, the faster these swirls are made. This helps measure how quickly the fluid is flowing.

There is a sensor beside the bluff body, which senses the vortices created. Each time a vortex is produced, it brings about some pressure variation that can be sensed by the sensor.

It measures the time between every vortex that it detects. This way, it calculates how fast the fluid is going. Because the speed of the fluid is related to the number of vortices, the meter can determine the flow rate through vortex patterns

Once the flow rate is calculated, the meter displays the information in a readable form, like the volume of fluid flowing through the pipe. It also sends this data to a control system for monitoring or further use.

The bluff body is placed inside the pipe, which creates disturbances in the flow of the fluid. Think of it like placing a rock in a stream of water. As the water flows around the rock, it creates swirling patterns or small waves (vortices). In a flow meter, this part helps create these swirls in the fluid, which are important for measuring flow.

The sensor detects these swirls (vortices) created by the bluff body. Imagine you had a gadget that could count how many waves hit the shore on a beach. Well, the sensor within the flow meter counts the number of these swirls occurring, which helps to determine the flow rate of the fluid.

The vortex transmitter takes the raw data collected by the sensor and converts it into an electronic signal that can be processed. Then, it sends these signals to the appropriate part, either to the display unit or the control system, for reading and taking action on the flow rate. Simply, it takes the information from the sensor and converts it into signals that can be understood.

The final result will be shown on the display unit. The display of a vortex flow meter is the interface that presents the results of flow measurements in a readable format. This helps the user check how much fluid or gas is flowing through the system in real-time. There are two main types of display systems: analog and digital

In an analog display, the flow rate is shown using a needle or dial that moves in relation to the flow. It gives a continuous visual indication of the flow, but it doesn’t provide precise numerical values.

A digital display shows the measurements of the flow in exact numbers, mostly on an LCD or LED screen. It delivers very precise readings and can even provide other information aside from its direct measurements, such as total flow, making it more adaptable and user-friendly.

The power supply is required to ensure the electrical energy flow, which makes the flow meter work. Both the sensors, transmitter, and display unit are required to remain powered continuously so that they can measure, process, and display the flow data correctly.

When it comes to ensuring precision and durability in vortex flow meters, choosing the right materials and designing with intent is everything. The correct combination can dramatically improve measurement accuracy, device longevity, and overall system performance.

The sensor assembly material must be compatible with both the fluid type and environmental conditions. Popular choices include:

Pro Tip: Stainless steel is often the go-to for industrial settings, but for harsh or specialized fluids, alternative materials may offer better long-term reliability.

The geometry of the flow element directly influences the vortex shedding process—key to accurate readings.

Each shape offers distinct advantages and limitations, so selecting the right design ensures optimized signal stability and accurate flow readings.

Assembly quality can make or break the performance of a vortex flow meter. Critical construction elements include:

Best Practices:

This method involves placing the flow meter directly into the pipe by cutting the pipe and installing the meter as part of the piping system. It's typically used for smaller pipes to ensure accurate measurement of fluid flow.

An insertion vortex flow meter involves the insertion of a probe or sensor into the pipe without cutting into or removing the pipe. It is often used for larger pipes and can measure the flow without disturbing the system heavily.

After installation, the flow meter is connected to the power supply and other control systems. Proper wiring ensures that it functions well and can record and transmit data for display or analysis.

Vortex flow meter calibration involves adjusting the flow meter to ensure it provides accurate measurements. This process compares the meter's readings with known standards and adjusts it to match the correct flow rates for its reliable performance.

Flow meters play quite an important role in the oil and gas industry by measuring the flow of liquids and gases accurately. They are used to monitor the movement of crude oil, natural gas, and other fluids through pipelines, helping ensure that operations run smoothly and efficiently.

Example: In offshore oil rigs, the vortex flow meters help to check for leaks of natural gas through pipelines and ensure that it is properly sent to the processing plant.

In the chemical and petrochemical industry, it measures the flow of different chemicals, acids, and gases during production and helps to handle aggressive chemicals and high temperatures, making it ideal for these industries.

Example: Here, too, a vortex flowmeter is used for various reasons. In a chemical manufacturing plant that produces sulfuric acid, vortex flow meters measure the flow of the acid at different points in the process.

Due to the corrosive nature of sulfuric acid, a vortex flow meter ensures that the exact quantity of acid is being transferred between reactors, which aids in keeping the end product safe and of high quality.

Vortex flowmeters are critical in the power generation industry to measure steam and water flow. They give accurate flow measurements, which are important to maintain efficiency and safety in boilers and turbines.

Example: In a thermal power plant, vortex flow meters measure the flow of steam to turbines, ensuring the plant generates electricity efficiently without wasting energy.

Here, it is used to monitor water flow in treatment plants. These meters help to manage water use and prevent overflows or underflows.

Example: In a wastewater treatment industry, vortex flow meters track the amount of wastewater occurring in the plant, helping operators ensure efficient treatment and avoid system overload.

These meters in the food and beverage industry are used to measure the flow of liquids like water, milk, or syrups in food production processes to ensure accurate measurement and maintain the quality and consistency of products.

Example: In a dairy factory, vortex flow meters measure the amount of milk being processed to make sure the right quantity is being used, preventing product loss.

Vortex flow meters measure the flow of water or air in HVAC systems to manage heating and cooling in buildings.

Example: In a large office building, vortex flow meters measure the flow of chilled water in the cooling system, which helps to reduce energy consumption and ensure consistent cooling.

In pharmaceutical manufacturing, vortex flow meters are used to measure the flow of gases or liquids like water, solvents, or chemicals. Precision is crucial in pharmaceuticals.

Example: In a pharmaceutical plant producing medicine, vortex flow meters measure the flow of purified water used for cleaning equipment, ensuring the water is used efficiently and consistently.

These meters measure the flow of water and steam in the paper and pulp industry.

Example: In a paper mill, vortex flow meters measure the flow of water used in the pulp-making process, ensuring the right amount is used to create high-quality paper.

Now, as we come to the end, it’s clear that vortex flow meters offer a reliable and versatile solution for measuring the flow of liquids, gases, and steam across various industries.

In general, vortex flow meters stand out as a reliable, cost-effective, and easy-to-use source of monitoring. Whether you're in control of steam flow within a power plant or managing gas flow for chemical processing, these meters will offer the accuracy and dependability necessary to ensure that any operation goes smoothly and efficiently in almost all industries.

If you are looking for a reliable, accurate, and low-maintenance solution for your flow measurement needs, check out our vortex flow meters today. We are a leading flow meter manufacturer and supplier in India, and see the difference they can make in optimizing your operations. Get in touch with us today to learn more or make your purchase!