- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Understanding Cone Flow Meters: Principles, Applications, and Advantages

Cone flow meters are becoming one of the most reliable and accurate flow measurement solutions for industries worldwide.

Designed with a flow-conditioning cone, these differential pressure (DP) flow meters improve accuracy, minimize turbulence, and provide consistent performance, even in harsh operating conditions.

In this guide, we’ll cover everything you need to know about cone flow meters, their working principle, key components, advantages, disadvantages, and industrial applications.

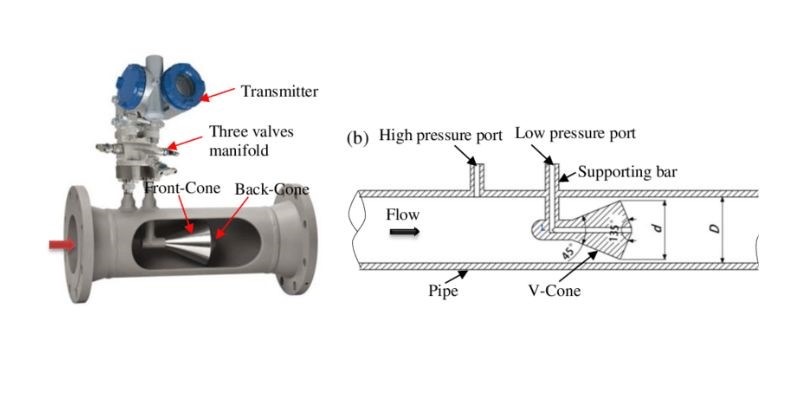

Key Components of a Cone Flow Meter

Flow Conditioning Cone

1. Flow Conditioning Cone

The cone, placed in the center of the pipe, distributes fluid evenly, reduces turbulence, and helps measure the flow rate accurately.

2. Inlet and Outlet Sections (Pipe Body)

- Inlet section: Where the fluid enters before reaching the cone.

- Outlet section: Allows fluid to stabilize after passing the cone.

The pipe body is typically made of stainless steel or titanium, ensuring durability under high pressure and extreme temperatures.

3. Differential Pressure (DP) Transmitters

These convert pressure readings into electrical signals for monitoring. Modern DP transmitters are integrated with industrial automation systems, allowing real-time data tracking and remote access.

4. Pressure Taps (Upstream & Downstream)

Two taps measure pressure, one before and one after the cone.

This setup eliminates turbulence effects, resulting in stable and precise flow measurement.

5. Flanges

Flanges secure the cone inside the pipe and connect the flow meter with the piping system, ensuring it remains stable under extreme flow conditions.

6. Temperature & Pressure Sensors

Sensors monitor temperature and pressure changes to account for variations in fluid viscosity and density, which directly affect flow accuracy.

Burak's Cone Flow Meters are engineered with precision components that ensure durability, reliability, and unmatched accuracy.

Working Principle of a Cone Flow Meter

Here’s how a cone flow meter works step by step:

1. Flow Enters the Meter

Fluid enters and hits the centrally placed cone, which spreads the flow evenly. Unlike other flow meters, cone meters don’t require long straight pipe runs for accurate measurement.

2. Cone Creates a Pressure Drop

As fluid passes through the narrow section around the cone, velocity increases and pressure decreases (Bernoulli’s principle). This creates a measurable differential pressure.

3. Measuring the Pressure Difference

- Upstream (before cone): Higher pressure

- Downstream (after cone): Lower pressure

A DP transmitter measures this difference to determine the flow rate.

4. Converting Pressure Data into Flow Rate

Using Bernoulli’s principle and flow equations, the pressure difference is converted into an accurate flow rate calculation, considering temperature, pressure, and fluid type.

Applications of Cone Flow Meters

Oil & Gas Industry: In the oil industry, it is used for measuring crude oil, natural gas, and multiphase flows in pipelines.

Chemical & Petrochemical Industry: Here, in the chemical industry, it measures the flow rate of aggressive, corrosive, and viscous chemicals.

Power Generation: For power generation, it is essential to measure the steam, cooling water, and fuel flow in power plants.

Water & Wastewater Treatment: In water and wastewater treatment, it is used to measure raw water intake, treated water distribution, and wastewater flow.

Aerospace & aviation: Cone flow meters are also used in rocket engines to test fuel measurement.

Food & Beverage Industry: Here, in the Food and beverage industry, it measures the flow of liquids like milk, juices, syrups, and soft drinks in processing plants.

Pharmaceutical & Biotechnology Industry: In pharmaceuticals, it is for precisely measuring the flow of liquid chemicals and gases in drug manufacturing.

Advantages of Cone Flow Meters

- Cone flow meters provide accurate and precise measurements even in turbulent or changing conditions

- Unlike orifice plates and Venturi meters, cone flow meters don’t require long upstream and downstream straight pipe sections. This makes them ideal for installation where space is limited.

- They can handle high pressure, high temperature, and corrosive environments. This makes them the right choice for oil & gas, power plants, and the chemical processing industry

- Since cone flow meters have no moving parts, they are highly durable and require minimal maintenance.

- These meters can work effectively with liquid, gas, and steam.

Disadvantages of Cone Flow Meters

- Due to their specialized design, cone flow meters are more expensive than traditional flow meters. However, their durability and low maintenance can counterbalance the initial cost over time.

- Cone meters perform well in medium- to high-flow rate applications but may struggle with very low flow rates.

- Cone flow meters are less common and produced by fewer manufacturers. This can make procurement, servicing, and replacement parts more difficult, especially in remote locations.

Discover the different types of flow meters and how they work.

Conclusion

Cone flow meters are an advanced and reliable choice for accurate flow measurement in demanding industries. While they may come at a higher cost, their durability, low maintenance, and precision make them a long-term investment.

Before selecting, always consider your application requirements, budget, and installation conditions to ensure maximum efficiency.

At Burak Metering, we manufacture precision-engineered cone flow meters designed for performance, durability, and accuracy across industries. Whether you’re in oil & gas, chemicals, power, or water treatment, we deliver solutions tailored to your needs.

Contact us today for expert recommendations and customized flow meter solutions.

FAQs about Cone Flow Meters

1. What is a cone flow meter?

A cone flow meter is a differential pressure (DP) flow meter that uses a cone-shaped element to condition the fluid, reduce turbulence, and measure flow accurately.

2. How does a cone flow meter work?

It works by placing a cone inside the flow path. As fluid passes around the cone, a pressure drop occurs. The differential pressure is measured and converted into flow rate.

3. Where are cone flow meters used?

Cone flow meters are used in oil & gas, chemical plants, power generation, water treatment, aerospace, food & beverage, and pharmaceutical industries.

4. What are the advantages of cone flow meters?

They offer high accuracy, no need for long straight pipes, durability in harsh conditions, minimal maintenance, and compatibility with liquids, gases, and steam.

5. What are the disadvantages of cone flow meters?

Cone flow meters are more expensive, less effective at very low flow rates, and have limited availability of spare parts compared to traditional meters.

6. Why choose Burak cone flow meters?

Burak provides precision-engineered cone flow meters that ensure long-term accuracy, durability, and efficiency—customized for your industry’s needs.