- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

Introduction to Orifice Meters for Accurate Gas Flow

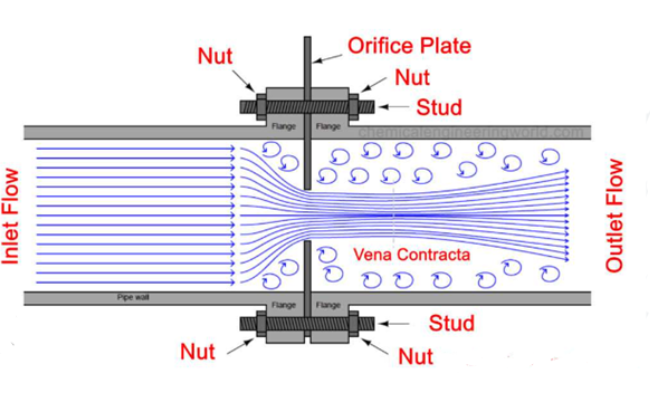

An orifice flow meter is a device used to measure gas flow rate through a pipe. It consists of a specially designed plate, known as an orifice plate, located within the pipe. As the gas flows through the plate, the pressure difference across it is measured, allowing for the calculation of the flow rate.

Orifice meters work on the principle of creating a constriction in the pipe, which leads to an increase in fluid velocity and a corresponding decrease in pressure. The pressure difference, known as the differential pressure, is measured using sensors connected to the orifice plate. The gas flow rate can be accurately determined by correlating the differential pressure with the known characteristics of the orifice plate.

Accurate gas flow measurement is crucial for various industries, including oil and gas, chemical manufacturing, and energy production. It enables companies to monitor and control gas consumption, optimize processes, and ensure compliance with regulatory requirements. Without accurate measurements, companies may face operational inefficiencies, safety risks, and increased costs.

Working Principle of an Orifice Meter

The orifice flow meter measures fluid flow rate by using the pressure drop created across an orifice plate placed in the pipeline. Below is a step-by-step explanation:

1. Fluid Entry

The fluid (gas or liquid) flows through the pipe and approaches the orifice plate, which is fixed perpendicular to the flow direction.

2. Flow Constriction

The orifice plate has a round hole that creates a flow restriction. As the fluid passes through this small opening, its velocity increases.

3. Pressure Drop

The increase in velocity causes a drop in pressure across the orifice. The pressure is higher on the upstream side and lower on the downstream side.

4. Differential Pressure Measurement

Pressure sensors or taps placed before and after the orifice plate measure the differential pressure. This pressure difference is directly related to the flow rate.

5. Flow Rate Calculation

The flow rate is calculated using Bernoulli’s equation and a known discharge coefficient. The discharge coefficient depends on the orifice plate dimensions, fluid type, and flow conditions.

6. Output and Monitoring

The calculated fluid flow rate is shown on a display or sent to a control system for monitoring and process control.

History of Orifice Meters

Early Development:

The concept of orifice meters can be traced back to the 17th century when scientists began exploring methods to measure fluid flow. However, it was not until the Industrial Revolution that orifice meters started to be used extensively in manufacturing processes.

Advancements over Time:

Over the years, significant advancements have been made in the design and performance of orifice meters. Innovations such as improved materials, refined orifice plate geometries, and enhanced pressure sensors have contributed significantly to their accuracy and reliability.

Current Applications and Industries:

Today, orifice meters find applications in a wide range of industries. They are used to measure gas flow in natural gas pipelines, monitor industrial processes, and even in residential gas meters. Their versatility and established performance make them popular for gas flow measurement.

Benefits and Limitations of Orifice Meters

Advantages:

Orifice meters offer several advantages that contribute to their widespread use. They are relatively simple and inexpensive compared to other gas flow measurement techniques. Additionally, they provide reliable and repeatable measurements in a wide range of operating conditions. Their sturdy design also allows for easy installation and maintenance.

Challenges and Limitations:

Despite their advantages, orifice meters do have some inherent limitations. One of the main challenges is the pressure drop caused by the orifice plate, which can lead to energy losses in the system. Furthermore, orifice meters are sensitive to variations in gas composition and require periodic recalibration to maintain measurement accuracy.

Comparison with Other Gas Flow Measurement Techniques:

Orifice meters are just one of several gas flow measurement techniques available. Other techniques include turbine flow meters, ultrasonic flow meters, and thermal mass flow meters. Each method has strengths and limitations, and choosing the most suitable method depends on the specific application requirements.

Understanding Key Terminologies

Orifice Plate:

The orifice plate is a critical component of the orifice plate flow meter. It is a specially designed metal plate with a precisely drilled hole, which creates the constriction necessary for flow measurement. The dimensions and shape of the orifice plate are carefully chosen to ensure accurate and repeatable measurements.

Differential Pressure:

Differential pressure refers to the pressure difference measured across the orifice plate in an orifice meter. It is proportional to the gas flow rate and provides the primary input for flow calculations. Differential pressure sensors are used to measure this pressure difference accurately.

Beta Ratio:

The beta ratio is the ratio of the diameter of the orifice hole to the inside diameter of the pipe. It affects the accuracy and rangeability of the orifice meter. A higher beta ratio typically results in lower accuracy but a larger rangeability, while a lower beta ratio offers higher accuracy but a limited rangeability.

Conclusion

As we delve into the significance of accurate gas flow measurement and the enduring role of orifice meters in various industries, it’s imperative to acknowledge the expertise of one of the leaders in this field, Burak Metering. As one of the best orifice meter suppliers, Burak Metering has been at the forefront of providing cutting-edge solutions in gas flow measurement.

Their commitment to quality, innovation, and precision has made them a trusted name in the industry.

Whether you are in oil and gas, chemical manufacturing, or any other sector requiring precise flow measurement, Burak Metering stands as a reliable partner. Choosing the proper orifice meter manufacturer is pivotal for ensuring the effectiveness of your operations. With Burak Metering, you can trust in a legacy of excellence that spans accurate and dependable gas flow measurement solutions.