Working Principle of Vortex Flow Meter

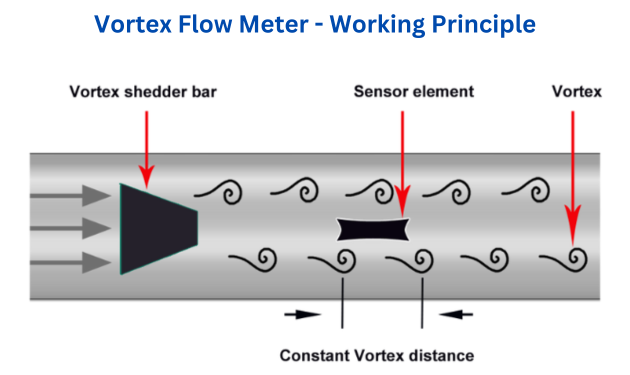

The Vortex flow meters operate on the principle of the von Karman effect, which involves the generation of vortices when a fluid flows past a bluff body (such as a triangular or rectangular bar) inserted into the flow path. Here’s how it works:

Bluff Body: A bluff body is strategically placed inside a meter body. As the fluid moves around this obstacle, it creates alternating vortices downstream. The frequency of these vortices is directly proportional to the velocity of the liquid.

Vortex Shedding: Vortices form alternatively on either side as the fluid flows past the bluff body. These vortices detach from the body at regular intervals, with the frequency of detachment being proportional to the velocity of the liquid. When the flow rate increases, the frequency of vortex shedding also increases.

Sensor Detection: The meter has a piezoelectric sensor near the bluff body to detect the vortices. Each time a vortex is shed, it creates a pressure pulse or disturbance. The sensor picks up these disturbances.

Calculating Flow Rate: By measuring the time interval between successive vortices detected by the sensor, the flow meter calculates the velocity of the fluid. Since the frequency of vortex shedding is proportional to the flow rate, the meter can determine the flow rate by analyzing these vortex patterns.

Output Display: The flow rate data obtained from the sensor is converted into a readable form (e.g., volumetric flow rate) and displayed on the meter or transmitted to a control system for monitoring and further analysis.

Vortex flow meters are known for their reliability, accuracy, and ability to measure flow rates in various fluids. They are widely used in industries such as oil and gas, chemical processing, water treatment, and more, where precise fluid flow measurement is crucial.