- Feedback

- About

- Certificates

- Clientele

- Installations

- Testimonials

- Contact

- Career

- Get Quote

A Comparative Guide to Thermal Mass Flow Meter vs. Ultrasonic Flow Meters

Accurate industrial stream quantification stands critical for operational effectiveness, safety compliance, regulatory adherence, and expenditure control across diverse industrial sectors.

Industry utilizes two primary technologies for gas volume assessment:

Each device serves a singular objective, yet they employ distinct principles for precise quantification.

Here we compare these technologies, highlighting their operational foundations, functional characteristics, benefits, drawbacks, and appropriate application areas.

We aim to equip industry professionals with knowledge to make informed selections for their specific requirements, understanding specifications along with long-term implications.

Selecting the proper volume sensing instrument directly influences total operational expenses, upkeep demands, and aggregate performance.

Discover a range of high-quality flow meters. Visit our product page!

Understanding the Basics – How They Work

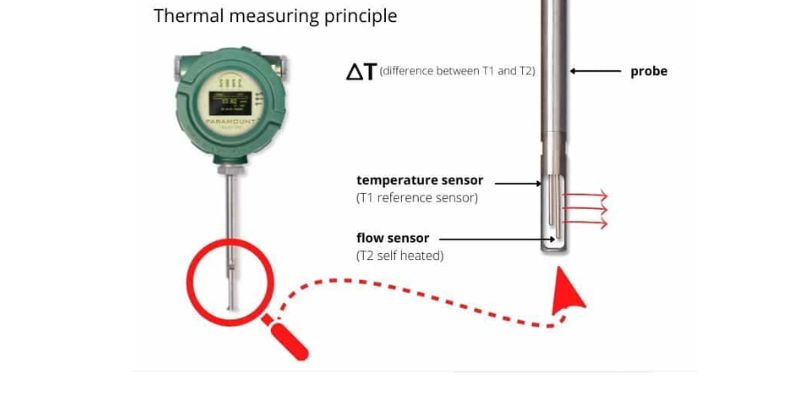

Thermal Mass Flow Meters: The Heat Transfer Principle

This instrument operates upon the principle of convective heat transfer. Its sensor measures thermal exchange between a heated element and the flowing stream. As the stream passes the heated component, it carries away heat, creating a temperature differential between the two sensors.

Technicians calculate the volumetric rate based on the reduction in thermal energy and the temperature difference, yielding a direct assessment of fluid velocity.

Learn more: Thermal Mass Flow Meter Explained: Everything You Need to Know

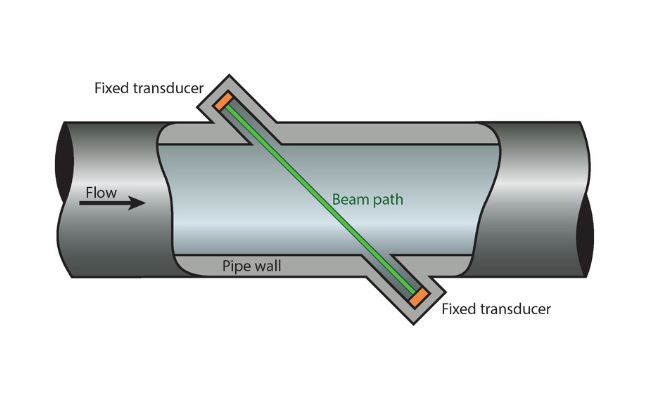

Ultrasonic Gas Flow Meters: The Sound Wave Propagation Principle

Ultrasonic gas flow meters, conversely, use the concept of sound wave propagation. They comprise two transducers; one functions as a transmitter, the other as a receiver.

The transmitter emits ultrasonic pulses into the flowing stream, and the receiver detects the duration these pulses travel against and with the current. By comparing these transit durations, the device determines the stream's speed and calculates its volumetric rate.

Learn More: Ultrasonic Flow Meters: Principles, Types, Advantages, and Applications

Key Performance Metrics & Operational Considerations – A Direct Comparison

Accuracy and Reliability in Diverse Conditions

Thermal mass flow meters offer high accuracy and precision, particularly in steady-state operations. They can assess fluid rates with an accuracy of ±1% and a repeatability of ±0.5%. However, swift alterations in process stream temperature and pressure can affect their accuracy.

Furthermore, these instruments are calibrated for a single stream makeup and assume consistent composition. Varying stream compositions can lead to significant errors.

For example, a high CO2 content might produce a 2% to 5% error, high propane 2% to 15%, and high hydrogen an astounding 100% to 300%.

Ultrasonic fluid sensing devices also provide high accuracy, typically within ±1% to ±2%. These instruments are less affected by shifts in stream temperature and pressure, providing dependable quantifications in dynamic situations.

Sensor Design: Intrusive vs. Non-Intrusive Measurement

A component is intrusive if any part extends into the pipe. Thermal mass fluid instruments typically feature an intrusive design, where sensors project into the pipe.

This makes them vulnerable to damage from high current velocities, such as those exceeding 120 m/s during a process blowdown. Solid particles like sand, wax, oil, or carbon, frequently present in "dirty" flare lines, further elevate the risk of impact damage.

Fouling, where deposits coat sensors, can also introduce substantial error, often necessitating a process shutdown for removal and cleaning. These devices can also introduce a pressure drop, affecting system efficiency.

Ultrasonic fluid quantifiers can be non-invasive or utilize "wetted but not intrusive" transducers. Some ultrasonic sensors incorporate drain plugs for liquid removal or allow high-pressure air jets for cleaning particles from transducers. This method eliminates pressure drops, simplifying system setup and reducing costs.

Turndown Ratio (Rangeability) for Variable Flows

Turndown ratio, or rangeability, represents the proportion between the maximum and minimum quantifiable current. It becomes key in flare assessments, where stream rates can range from a pilot flame to urgent blowdown conditions. A high turndown ratio offers appropriate sensitivity across the entire potential flow spectrum, allowing detection of leaks or open valves.

Many thermal mass flow meters report extensive possible current ranges yet have low turndown ratios (e.g., 100:1 for a 0.1-300 m/s range). Practically, this demands a compromise between an extensive range and low sensitivity. If a user desires a maximum current of 120 m/s, the minimum detectable current becomes 1.2 m/s, insufficient for pilot flame quantification.

Piping Requirements and Flow Profile

The "shape" of the fluid's path within a pipe is known as its flow profile. This profile varies significantly with pipe configuration and is vital for accurate quantification. Most meters assume a specific flow profile, with "fully developed" or bullet-shaped profiles being easiest to model. Disturbed flows, featuring turbulence or swirl, are harder to assess. More straight pipework generally means more accurate assumptions.

Thermal mass fluid instruments, being intrusive, can disrupt flow profiles. Consequently, these devices typically demand longer straight pipe runs (e.g., 20 pipe diameters upstream and 10 downstream) to mitigate these effects. They perform a point assessment at the pipe's center, assuming a perfect profile across the remaining diameter.

In contrast, ultrasonic flow meters require shorter straight pipe runs (e.g., 10D upstream and 5D downstream). This offers installation convenience and can yield significant cost savings. Ultrasonic devices conduct cross-pipe assessments, sending signals across the entire pipe diameter. This method gathers more data, leading to more valid assumptions about the flow profile, even in moderately disturbed conditions.

Maximum Pipe Size Capabilities

Thermal mass current meters must extend to the pipe's center, imposing a mechanical limit on their dimensions. Most models can be supplied for pipes up to a maximum diameter of 72 inches. For ultrasonic devices, no mechanical limitations exist.

Data Output and Power Consumption

Thermal mass fluid meters primarily provide current rates solely in terms of mass stream. They also consume greater power because their sensors require heating to maintain the necessary temperature differential.

Ultrasonic fluid instruments can supply a mass stream or a volumetric stream. Additionally, they provide average molecular weight, density at standard and operational conditions, and simple readings for temperature and pressure.

Beyond the Specs – Advanced Considerations for Selection

Total Cost of Ownership (TCO) – A Long-Term View

Ultrasonic instruments generally involve higher initial costs compared to thermal mass fluid meters. When considering the total cost of ownership, one should also examine installation expenses, including labor, commissioning, and potential pipe modifications.

Calibration costs and frequency are also important.

How often does each device type require recalibration? What are the associated service fees, and what is the potential downtime?

For thermal instruments, providing detailed stream composition data may be necessary for multiple factory calibrations. Maintenance expenses involve quantifying routine upkeep, cleaning (including potential process shutdown costs for intrusive thermal instruments), and replacement components over the instrument's operational life.

Finally, a comparative analysis of energy consumption costs over several years offers additional perspective.

Integration and "Smart" Capabilities for Modern Industrial Environments

Modern industrial facilities demand advanced device integration. Connectivity remains paramount; one should consider common industrial communication protocols (e.g., Modbus, HART, Profibus, Ethernet IP, OPC UA) that each instrument supports.

System integration involves how easily these devices connect with Distributed Control Systems (DCS), SCADA systems, or data historians. Additionally, advanced features like self-diagnostic capabilities, predictive maintenance functions, or edge computing for Industry 4.0 applications significantly boost operational effectiveness.

Regulatory Compliance and Certifications

Adherence to industrial standards is crucial. Consider hazardous area certifications (e.g., ATEX, IECEx, or local equivalents) for use in explosive atmospheres. For applications demanding precise billing, custody transfer approvals (e.g., OIML, NTEP) indicate suitability. Other relevant industry standards, such as ISO for quantification uncertainty or AGA for natural stream assessment, also play a role.

Discuss your specific needs with our flow measurement specialists.

Ideal Applications – Matching the Meter to Your Needs

Thermal Mass Flow Meter's Ideal Applications

Thermal mass current instruments find extensive use in industries such as:

- Chemical processing: Assessing and managing stream rates in diverse chemical reactions.

- Energy management: Observing the stream in HVAC systems and boilers.

- Environmental monitoring: Emission observation in waste treatment facilities and manufacturing processes.

- General: Operations requiring excellent accuracy and repeatability in steady-state conditions across a wide range of streams.

Ultrasonic Gas Flow Meter's Ideal Applications for Demanding Environments

Ultrasonic stream sensing devices find preference in industries like:

- Oil and gas: Assessing stream rates in pipelines, custody transfer, and well testing.

- Power generation: Observing streams in turbines and cogeneration systems.

- Petrochemicals: Precise assessment of streams in refining and petrochemical processes.

- Flare Gas Measurement: This technology proves most appropriate due to its high turndown, resilience to varying stream compositions, and ability to withstand dirty flows and high velocities.

- General: Operations demanding dependable quantifications in dynamic stream conditions, with varying stream compositions, extensive pipe sizes, and where non-invasive assessment or minimal pressure drop is essential.

Get a custom assessment for your next industrial flow meter.

Conclusion: Making Your Informed Decision

Both thermal mass flow meters and ultrasonic gas flow meters deliver dependable and precise assessments of stream rates.

However, their strengths manifest in different situations. The optimal selection depends on your particular application, stream composition, system demands, and budget considerations.

By carefully weighing the advantages, limitations, and application areas of each technology, professionals can choose the most fitting stream sensing device to meet their objectives.