Phone

Phone

In today's industries, whether it's energy, manufacturing, or even HVAC systems, measuring gas flow is essential. That's where Thermal mass flow meters come in from manufacturing to environmental monitoring.

These devices help to measure how much gas is flowing through a system. They are known for their accuracy and reliability, which make them valuable tools for many applications.

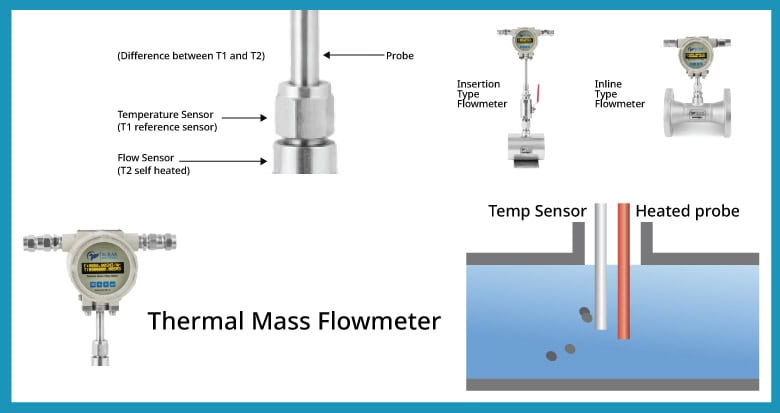

Thermal mass flow meter works by using heat. They have a heating element and temperature sensors that measure the flow of gas by checking how much heat the gas absorbs as it moves through the device. Because of their effectiveness, thermal mass flow meters are commonly used in industries like oil and gas, chemical processing, and HVAC systems.

In this blog, we will look at the different types of thermal mass flow meters, their benefits and drawbacks, and where they are used. By the end, you'll get a better understanding of these important devices and how they help keep operations running smoothly.

The heating element is the part of the flow meter that generates heat and when gas flows through the meter, this heating element heats up, and this heat gets absorbed by the passing gas. It is just like how the cold breeze cools you down in summer.

After that, the amount of heat absorbed by the gas helps the meter figure out the flow rate. the faster the gas moves, the more heat it takes away, allowing the meter to measure the flow.

These thermal flow sensors are crucial because they measure the temperature difference in the gas as it passes through the meter. There are usually two types of sensors used:

Thermocouples: These sensors measure the temperature difference between two points (before and after the heating element). They are simple and reliable.

RTDs (Resistance Temperature Detectors): These are more precise and work by measuring changes in resistance as the temperature changes. RTDs offer higher accuracy compared to thermocouples and are often used in more sensitive applications.

Together, these sensors help detect how much heat the gas absorbs, which tells the meter how fast the gas is flowing.

That is the pipe or tube where the gas travels. The flow body holds the heating element and temperature sensors, making sure the gas flows smoothly. It can be in the form of an inline type (a part of the pipeline) or an insertion type (a probe inserted into a pipe), depending on the application.

The controller is like the brain of the flow meter. It will gather all the raw data collected by the temperature sensors and heating element, and further process it to work out the flow rate of gas, thus, it manages how the flow meter operates and ensures everything is well in place.

The power supply is what keeps the flow meter running. It supplies electricity through the heating element, sensors, and other parts of the system. In case the power supply is improper then this flow meter will not be able to measure any gas flow precisely or work at all.

The screen will give you the result. It will provide you with critical information, including flow rate and temperature. Total gas consumption is sometimes displayed. The display can be digital or analog. which allows users to see the performance of the flow meter in real-time.

The working principle of a Thermal mass flow meter is based on the concept of heat transfer and the cooling effect caused by the flow of a gas or fluid. Here's a step-by-step explanation of how a thermal mass flow meter operates:

Sensor Element: The core component of a thermal mass flow meter is the sensor element. This element typically consists of two temperature sensors: a heated sensor (the mass flow sensor) and an unheated sensor (the reference sensor). Both sensors are positioned in the flow stream.

Heating the Mass Flow Sensor: The heated sensor is designed to maintain a constant temperature higher than the measured fluid or gas. It is heated using a small heating element.

Measuring Temperature Difference: As the gas flows through the meter, it carries heat away from the heated sensor. The unheated reference sensor measures the actual temperature of the gas. The difference in temperature between the heated sensor and the reference sensor is directly proportional to the mass flow rate of the gas.

Calculation: The meter's electronic circuitry calculates the flow rate based on the temperature difference between the two sensors. This calculation uses specific algorithms or calibration data considering sensor characteristics and gas properties.

Output: The calculated mass flow rate is typically displayed digitally or transmitted as an analog or digital signal for monitoring and control.

A thermal flow meter measures the flow of gases by heating one of its sensors and monitoring the temperature difference between the heated sensor and the reference sensor. The cooling effect caused by the flowing gas results in a temperature differential that is directly related to the mass flow rate and this relationship is used to calculate and output the flow rate information. This method provides a highly accurate and reliable means of measuring gas flow, particularly in applications where precision is crucial.

In a two-temperature thermal mass flow meter, there are two temperature sensors. One sensor measures the temperature of the gas that flows through, and the other sensor is heated. The gas passes by both sensors. As the gas flows past the heated sensor, it cools it down depending on how fast the gas is moving. The difference in temperature between the two sensors tells us the rate of the gas flow.

Example: Imagine you hold a cup of hot tea. If you blow gently over the cup, the air will cool the tea slightly. If you blow harder, then the tea will cool down quickly. The two sensors in the flow meter work similarly. One is the "hot tea" sensor and the other measures how much cooling occurs, just like how fast you blow on the tea. The higher the flow rate of gas, the more cooling occurs, and that calculates the flow rate.

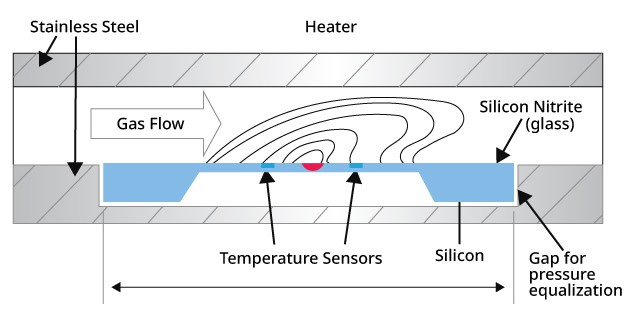

MEMS-based thermal mass flow meters use tiny, micro-sized sensors on a chip. These sensors detect the heat changes as the gas flows over the chip. Like in the two-temperature method, the gas cools the heated part of the sensor, and this cooling effect is used to determine the flow rate. Because the sensors are so small, they can measure very small changes in gas flow with great precision.

Example: It's sort of like a delicate tiny fan. If you blew very gently on it, it would respond slightly. If you blew harder, it would respond faster. That MEMS sensor is actually like that tiny little fan, sensing the smallest puff of gas passing over it and adding it to the calculation of how fast that gas is moving.

In an inline installation, the thermal mass flow meter is installed as part of the pipeline itself. Flow sensors and heating elements are placed inside the meter to measure the flow.

In an insertion installation, the flow meter is inserted into an existing pipe or duct. Thus, the meter does not replace a portion of the pipeline but instead places its probe into the gas stream, and from there the sensors and heating element can measure the flow from within the pipe itself.

Once the thermal mass flow meter is installed, it must be hooked up to the control system. This means wiring the meter to a transmitter or controller so that the data collected can be processed and displayed.

Calibration ensures that the flow meter is reading correctly. Calibration is the process of making adjustments in the settings of a flow meter so that the readings produced by it appear to correspond to an accepted standard.

In the oil and gas industry, thermal gas flow meters are essential for measuring the flow of gases like natural gas, methane, and carbon dioxide. These meters help in:

Since this is an industry where safety is given utmost priority, the application of thermal mass flow meters makes it easy to monitor the levels of gas flow accurately, thus it reduces the risk and maintains high efficiency.

In the chemical industry Thermal mass flow meter deals with gases like hydrogen, nitrogen, and ammonia which further helps in:

In Power generation thermal mass flow meters are utilized to enhance the combustion processes in power plants by measuring the air and gas flow. This helps in:

In this food and beverage industry, thermal mass flow meters are employed to measure gases like carbon dioxide, nitrogen, and oxygen. which helps in:

In pharmaceutical manufacturing, thermal mass flow meters are used for controlling gas flows during the production of medicines. This includes:

Thermal mass flow meters play a huge role in environmental monitoring and managing gas emissions across various industries and help to monitor:

In water treatment industries, thermal mass flow meters are used to measure the flow of gases that support purification and aeration processes. such as:

In semiconductor manufacturing, precise gas measurement is significant. Thus here Thermal mass flow meters are employed to:

Thermal mass flow measurements are very accurate. Because precise technology is used while measuring the quantity of gas passing through. Such precision is important, especially in industries where exact gas measurement is needed to guarantee efficiency, cost control, and safety.

For example: In the pharmaceutical industry, the exact amount of gases like oxygen or nitrogen is used in drug production. Which needs to be carefully monitored to maintain product quality.

Another major advantage of thermal mass flow meters is their ability to accurately measure very low gas flow rates, That's because other types of flow meters cannot accurately do it. Besides, they easily handle various temperatures and pressures without reducing their accuracy.

For example: In environmental monitoring, where gases might flow at very low rates, such as methane or carbon dioxide. Regardless of changes in temperature or pressure, the meter continues to provide reliable readings without any change.

Fast response time is another quite good feature of thermal mass flow meters that makes them measure gas flow as soon as changes occur.

For example: In industries like power generation, real-time control of gas flow is important to maintain operational efficiency, the fast response time of a thermal mass flow meter allows for quick adjustments.

Thermal mass meters are designed to function for long periods in aggressive or extreme conditions. Examples of such conditions are extreme temperatures, high humidity, or exposure to corrosive gases. Their good design enables them to maintain performance in challenging industrial situations.

For example: In the oil and gas industries, thermal mass flow meters are exposed to high temperatures, moisture, and possibly corrosive gases. Under such conditions, the meter offers accurate measurements.

Different types of gases can be measured by the thermal mass flow meters with minimal recalibration. This flexibility and ease make it highly applicable in processes wherein different types of gases are processed within the same process stream.

For example: In chemical processing plants, where gases like hydrogen, nitrogen, and oxygen are used in different stages of production, a thermal mass flow meter can seamlessly switch between measuring these gases without requiring frequent recalibration. This flexibility reduces downtime and increases operational efficiency.

Thermal mass flow meters are designed for gases, and they actually cannot be used on liquids. Thus it is limited to gas applications only.

For example: In a water treatment or chemical processing industry where both gases and liquids need to be measured, another sort of liquid flow meter like a magnetic flow meter or ultrasonic flow meter will be needed to measure them separately.

Thermal mass flow meters require cleaned gases for obtaining real measurements since interference with dirt, dust, or other particles in the gas or on the sensor will lead to inaccurate or unreliable measurements.

Example: In a power plant where one might use natural gas or steam, dirt or moisture in the gas will affect the accuracy of a flow meter. Over time these particles would eventually accumulate on the sensor, leading to incorrect measurements or even requiring maintenance to clean or replace the meter.

Thermal mass flow meters are generally more expensive as compared to other types of flow meters. Though its benefits outweigh this initial expense still this advantage can make them less effective for projects with limited budgets. though its benefits outweigh this initial expense

Example: For instance, the capital cost of installing a thermal mass flow meter could be very high compared to the cost of installing other simpler meters.

These are not very successful high-pressure applications, though, since some gases move under very high speeds or pressure levels. In such cases, other flow meters, such as differential pressure or turbine meters, may be more suitable.

For example: It may not be an ideal application in an oil refinery that uses high-pressure pipelines to transport gases.

One problem in MEMS-based thermal mass flow meters is that sometimes they suffer from high or fluctuating temperatures. The extremes of temperature can affect the meter's performance and thereby impact the accuracy of readings.

For instance, in the production of semiconductors that involves controlling or regulating gas at different temperatures, a thermal mass flow meter using MEMS would not likely be the solution of choice because the sensor might experience difficulty with temperature adjustments within shorter time intervals, and this will impact the result in terms of accuracy for the measured gas.

Now you know, thermal mass flow meters provide a reliable and accurate means to measure the flow of gases. They work on the principle of heat transfer and find application in most industries because they can measure low flow rates with high precision.

Generally, investing in a thermal mass flow meter will benefit companies to a huge extent, by making the processes much more efficient, saving energy, and providing accurate measurements of gases. Thus, a Thermal mass flowmeter is a very good option for companies seeking reliable, robust, and less-maintenance flow measurement solutions.

If you're looking for a high-quality thermal mass flow meter that meets your specific needs, our team is here to help. We offer a range of reliable, durable, and low-maintenance flow measurement solutions. Contact us today to know more or make your purchase.