Working Principle of Venturi Flow Meter

The Venturi flow meter operates on the principle of differential pressure, utilizing a Venturi tube to measure the flow rate of fluids. Here’s a step-by-step explanation of its working principle:

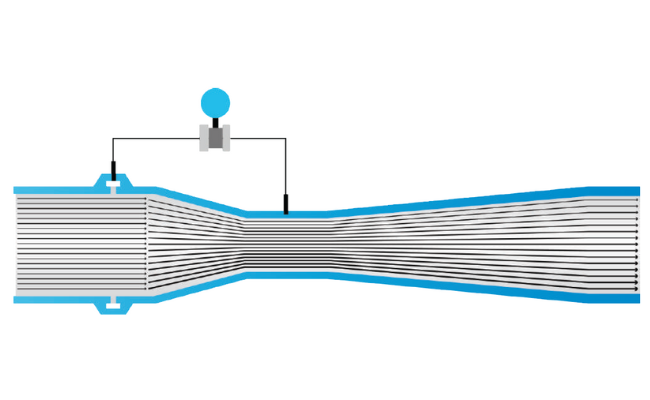

Fluid Flow Introduction: The fluid (liquid, gas, or vapor) enters the Venturi tube through the inlet section, which has a gradual converging shape.

Converging Section: As the fluid moves through the converging section of the tube, its velocity increases due to the reduction in cross-sectional area.

Throat Section: The fluid then passes through the throat of the Venturi tube, the narrowest part of the meter. At this point, the fluid velocity is at its maximum, and according to Bernoulli's principle, the pressure is at its minimum.

Diverging Section: After the throat, the fluid enters the diverging section of the tube, where the cross-sectional area gradually increases, causing the fluid velocity to decrease and the pressure to recover.

Pressure Differential Measurement: Pressure sensors are placed at the inlet (before the converging section) and at the throat. The difference in pressure between these two points (the pressure differential) is measured.

Flow Rate Calculation: The pressure differential is directly related to the flow rate of the fluid. Using Bernoulli’s equation and the continuity equation, the flow rate can be calculated accurately from the measured pressure differential.

Output and Monitoring: The calculated flow rate is then transmitted to a flow computer or display unit for monitoring and control purposes.

This method ensures high accuracy, reliable performance, and minimal pressure loss, making Venturi flow meters suitable for a wide range of industrial applications.