Working Principle of Ultrasonic flow meter

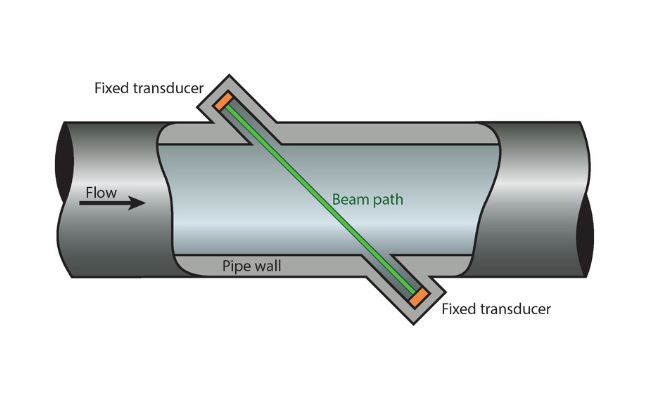

Ultrasonic gas flow meters operate on the transit time principle, where ultrasonic sound waves are transmitted both upstream and downstream through the gas. The difference in transit times between the upstream and downstream signals is directly proportional to the velocity of the gas.

Flow Rate Calculation: The velocity of the gas is multiplied by the cross-sectional area of the pipe to calculate the volumetric flow rate.

Temperature and Pressure Compensation: The meter measures real-time gas conditions, enabling accurate calculations of gas density and compressibility factors. Compensation algorithms, often based on standards like AGA8, adjust the volumetric flow to provide precise mass flow measurements, accounting for variations in gas composition and operating conditions.

Single-Path Model: Single-path models use one ultrasonic path and are suitable for applications that require basic flow measurement accuracy.

Dual-Path Model: Dual-path models enhance accuracy by averaging measurements from two independent paths, reducing the impact of flow profile disturbances.

Multi-Path Model: Multi-path models utilize multiple ultrasonic paths to capture detailed flow dynamics, delivering the highest accuracy for large-diameter pipes or critical industrial processes.

Inbuilt Electronic Volume Corrector (EVC): The inbuilt EVC processes data from the ultrasonic measurements and the temperature and pressure sensors. It converts the actual flow volume to standard conditions, ensuring precise billing and reporting in compliance with industry standards.

Efficient and Reliable Design: The design of the ultrasonic gas flow meter ensures no obstruction to the gas flow, resulting in zero pressure drop. Its minimal maintenance requirements make it an efficient and reliable solution for industrial gas applications.