Working Principle of Coriolis Mass Flow meter

The working principle of a Coriolis mass flow meter is based on the Coriolis effect, which occurs when a fluid flows through a vibrating tube. Here’s a step-by-step explanation of how it works:

Tube Vibration: The flow meter contains one or more flow tubes that are set into a continuous vibrating motion by an external actuator. This vibration is typically at a right angle to the direction of the flow.

Fluid Flow: As the fluid enters the vibrating tube, it experiences an oscillating motion due to the vibration.

Coriolis Force: When the fluid moves through the vibrating tube, it encounters a Coriolis force. This force causes the tube to twist in proportion to the mass flow rate of the fluid. The amount of twist is directly related to the mass flow rate of the fluid.

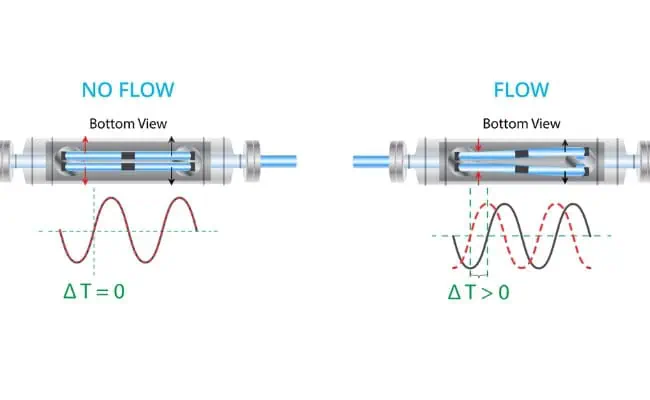

Phase Shift Detection: Sensors placed at different points along the vibrating tube detect the phase shift caused by the Coriolis force. This phase shift is the result of the time delay between the vibrations at different points along the tube.

Signal Processing: The detected phase shift is proportional to the mass flow rate. The flow meter’s electronics process this signal to calculate the mass flow rate of the fluid.

Density and Temperature Measurement: Many Coriolis meters also measure the fluid's density by analyzing the natural frequency of the vibrating tube, which changes with the density of the fluid. Additionally, temperature sensors are often integrated to provide temperature compensation and improve measurement accuracy.

Output: The processed signals are used to output the mass flow rate, fluid density, and, in some cases, fluid temperature. This data can be transmitted to control systems or displayed locally.