Influent Flow

As wastewater enters the treatment plant, the first thing to do is measure its flow. This helps determine the treatment plant's capacity and adjust the treatment processes accordingly. It's like knowing how much dirty laundry you have before starting the washing machine – you must change the cycle depending on the load.

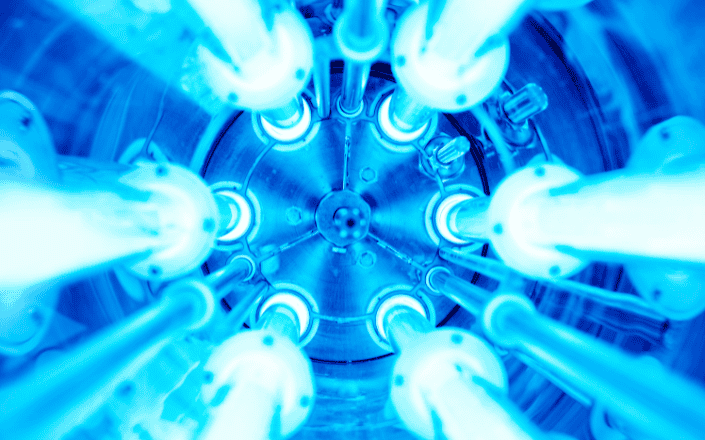

Aeration Air Flow

In wastewater treatment, oxygen is essential for breaking down organic matter. Flow meters monitor the airflow into aeration tanks, ensuring enough oxygen is available for the hungry microbes doing the cleaning work. Imagine these microbes as tiny Pac-Mans gobbling up pollution – the flow meter keeps the oxygen pellets coming so they can work efficiently.

Sludge Thickening and Dewatering

After treatment, wastewater leaves behind a sludge residue. Flow meters help manage this sludge by monitoring its flow during thickening and dewatering processes. This reduces the sludge volume and makes it easier and cheaper to handle. Think of it as wringing out a wet sponge – the flow meter tells you how much water is left and when to stop squeezing.

Effluent Discharge

Finally, the treated wastewater is ready to be released into the environment. But before it goes, flow meters one last time measure its flow to ensure compliance with discharge regulations. It's like a final quality check before the water is sent back into the world, ensuring it meets all the necessary standards.

Solution of flow measurement provided by Burak Metering:

Flow measurement is critical in wastewater treatment, ensuring efficient processing and environmental compliance. Magnetic, Ultrasonic, Venturi and Open Channel flow measurements accurately quantify wastewater flow, optimizing treatment plant operations and meeting regulatory standards. Advanced sensors and analytics enable effective management, enhancing treatment efficiency and environmental protection.

Burak recommended models are: Burak Vortex Flow Meter BX-6000-G & Burak Electromagnetic Flow Meter BE-5000-G.