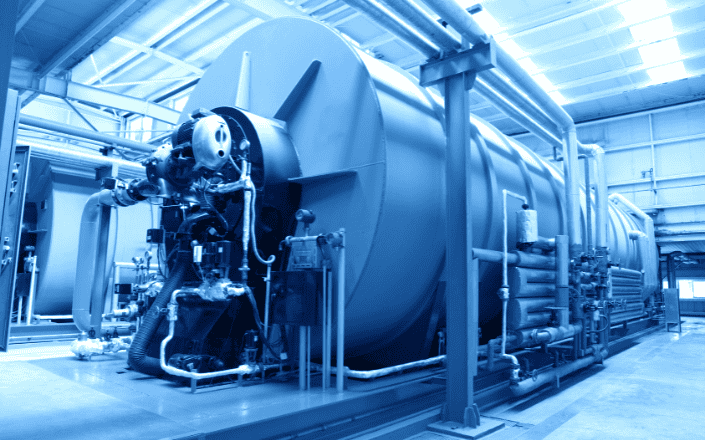

Boiler Feedwater Measurement in Power Plants

Boiler Feedwater measurement is a critical aspect of power plant operations. This process involves precisely measuring the flow of water entering the boiler system. Accurate measurement ensures that the appropriate amount of water is supplied for steam generation. The Feedwater measurement typically employs flow meters in the pipeline delivering water to the boiler. These flow meters are designed to provide real-time data on the water flow rate. This data aids in maintaining optimal boiler performance by ensuring a consistent and regulated water supply. Accurate Feedwater measurement ensures efficient steam generation and contributes to the boiler system's longevity and safety by preventing issues like overheating or inadequate water supply, which could lead to equipment damage or operational inefficiencies. Therefore, implementing reliable flow measurement systems for Boiler Feedwater is fundamental in optimizing power plant performance.