Production Monitoring in Chemical Industry

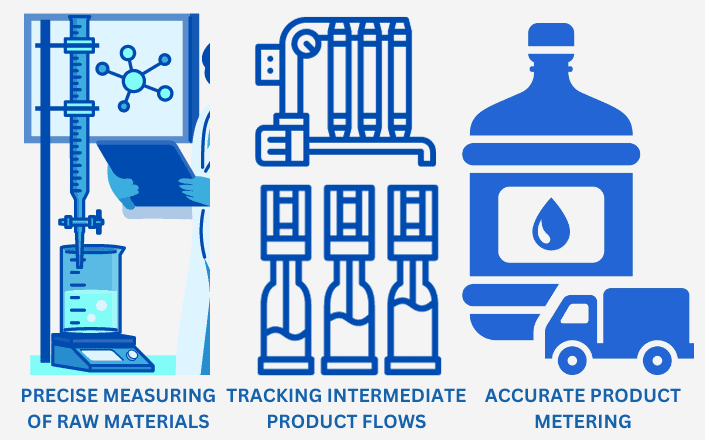

Production monitoring within the chemical industry involves the continuous observation and management of various manufacturing processes. It encompasses real-time tracking and analysis to ensure that production remains efficient, safe, and of high quality. This monitoring involves overseeing chemical reactions, temperatures, pressures, and other critical parameters to maintain optimal conditions. Regular checks are conducted to confirm that the chemical compounds meet stringent quality standards and comply with regulatory requirements. Efficient resource utilization is also a crucial aspect, ensuring minimal waste while optimizing the usage of raw materials, energy, and water. Simultaneously, monitoring equipment performance ensures that machinery operates effectively within specified parameters, minimizing downtime through timely maintenance. Safety is a primary concern, and production monitoring involves consistent oversight to ensure compliance with safety protocols and regulatory standards, thereby maintaining a secure working environment. Modern production monitoring systems leverage advanced technologies such as sensors, automation, and data analytics. These tools enable real-time data collection, analysis, and predictive maintenance, empowering proactive decision-making and process optimization. Ultimately, production monitoring in the chemical industry aims to consistently deliver high-quality products while maximizing efficiency and safety across manufacturing operations.